J

jassin000

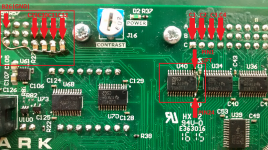

I was thinking k30 to tap the pads yes, but after seeing the post about the leg lift... Yup that one seems like the easiest to do.

I'm not jumping the gun to fix what I've never really seen as a major problem anyways. So of course I'm going to have a look at what DS is cooking up for us before deciding on anything.

I'm not jumping the gun to fix what I've never really seen as a major problem anyways. So of course I'm going to have a look at what DS is cooking up for us before deciding on anything.