TheRiddick

Student

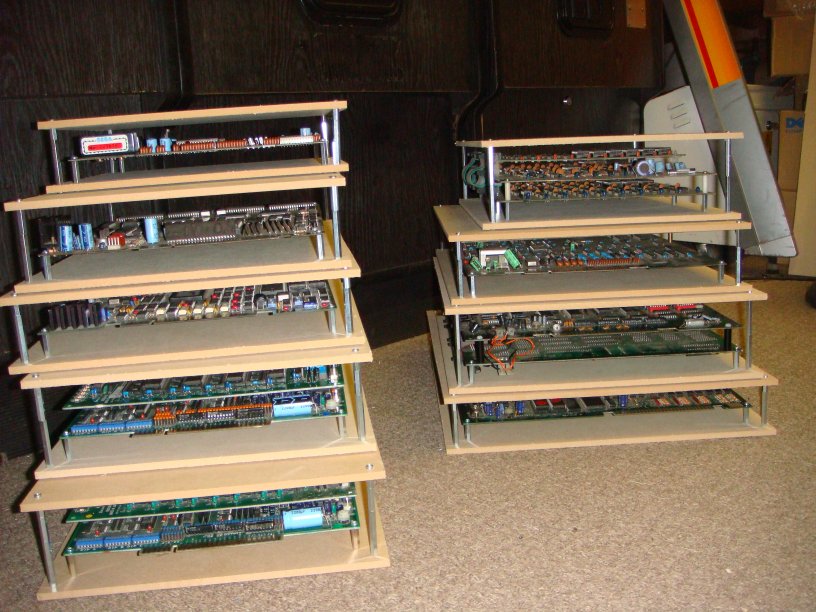

Question i'm looking for a way to protect my PCB because I only have 1 cab and i take them out back and forth.

I saw a picture before that somebody had Jamma Board PCB feet on each side with glass above and below to protect your pcb from getting scratched.

Wondering if this is a good idea and if so who sales something like this.

or

is there something better?

Any help would be amazing

Thanks,

I saw a picture before that somebody had Jamma Board PCB feet on each side with glass above and below to protect your pcb from getting scratched.

Wondering if this is a good idea and if so who sales something like this.

or

is there something better?

Any help would be amazing

Thanks,