Maverick1978

Student

Hey folks. So as some of you may have seen, I've recently purchased a blast city (sega bass fishing) on the cheap for $300 locally.

I speak about it here: Blast city value?

Here's the monitor problem as told to me by previous owner: "He says he connected a 645 in 1 heros of the storm 2 and it wouldn't rez to the screen. He hooked it up to another 31khz monitor and it came on. S he thought it was a loose vga wire, so he tightened it and tried again. He heard a screech and the monitor shut off. From there on it flashes on briefly then shuts off again. Sometimes it stayed on but for the most part it doesn't, so he pulled the monitor to visually inspect but didn't see anything."

So the previous owner had the monitor pulled from the cabinet when I purchased it. I've been really careful to not touch the neck, to transport it carefully home, and it's sat untouched - until today.

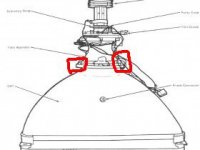

I go to pull the chassis to mail out to pnl. I discharge the tube, then go to carefully pull the yoke board from the neck... When the whole neck tube moves. Wtf?? So I hold the neck in place, pull the yoke board, pull the chassis, and I try and see what I'm left with...

Ultimately, the neck is unbroken in and good visible shape. It sits nice and looks normal - until one lifts up on the back of the neck tube, where the entire thing raises as the "goo" that holds it to the crt tube are broken on left/right/bottom. Top portion is affixed still.

So... My question. Could this be the whole problem? And is it fixable - without sending it off?

I've a pic of the left of the neck tube as I'm lifting slightly.

I speak about it here: Blast city value?

Here's the monitor problem as told to me by previous owner: "He says he connected a 645 in 1 heros of the storm 2 and it wouldn't rez to the screen. He hooked it up to another 31khz monitor and it came on. S he thought it was a loose vga wire, so he tightened it and tried again. He heard a screech and the monitor shut off. From there on it flashes on briefly then shuts off again. Sometimes it stayed on but for the most part it doesn't, so he pulled the monitor to visually inspect but didn't see anything."

So the previous owner had the monitor pulled from the cabinet when I purchased it. I've been really careful to not touch the neck, to transport it carefully home, and it's sat untouched - until today.

I go to pull the chassis to mail out to pnl. I discharge the tube, then go to carefully pull the yoke board from the neck... When the whole neck tube moves. Wtf?? So I hold the neck in place, pull the yoke board, pull the chassis, and I try and see what I'm left with...

Ultimately, the neck is unbroken in and good visible shape. It sits nice and looks normal - until one lifts up on the back of the neck tube, where the entire thing raises as the "goo" that holds it to the crt tube are broken on left/right/bottom. Top portion is affixed still.

So... My question. Could this be the whole problem? And is it fixable - without sending it off?

I've a pic of the left of the neck tube as I'm lifting slightly.

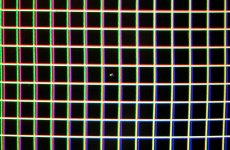

There's 4 of them: top, bottom, left, right. B/L/R have given way and there is some movement away from the CRT itself. It's unknown if there is forward movement into the CRT display that would, as XeD suggests, cause color impurity.

There's 4 of them: top, bottom, left, right. B/L/R have given way and there is some movement away from the CRT itself. It's unknown if there is forward movement into the CRT display that would, as XeD suggests, cause color impurity.