xodaraP

Legendary

As soon as @Mitsurugi-w and @Darksoft decide what the best repair option is I'm sure they'll let you know, depending on how it's all wired up you may have to ship it to the US or potentially Europe.

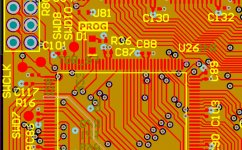

If it's something I can fix (meaning something where the ARM chip doesn't have to be removed or other major stuff) then we'll get it done. You'll have to be patient.

If it's something I can fix (meaning something where the ARM chip doesn't have to be removed or other major stuff) then we'll get it done. You'll have to be patient.