Yubm12

Enthusiast

weird - 100Yen coins get stuck in credit validator on mine100yen

Just 100yen.

weird - 100Yen coins get stuck in credit validator on mine100yen

Just 100yen.

any tips i should know about using that IWISS crimping tool? My parts should be here from digikey this week and hopefully i can find time this weekend to dive inYep, that's Universal Power. On your cabinet you need these for the main controls: https://www.digikey.com/en/products/detail/te-connectivity-amp-connectors/176299-1/2328051

And these for the kick harness: https://www.digikey.com/en/products/detail/te-connectivity-amp-connectors/176288-1/5124015

And these contacts: https://www.digikey.com/en/products/detail/te-connectivity-amp-connectors/175153-1/1149439

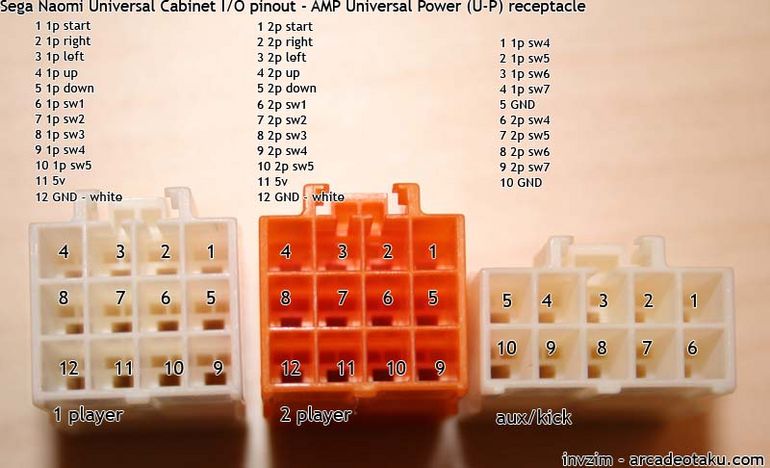

Pinouts for the receptacles you're building:

Pinout of the plugs connecting to them (that you have premade, but make sure it matches just in case):

Sure. On the Iwiss, you want to use the third from left section for AMP-UP contacts.any tips i should know about using that IWISS crimping tool? My parts should be here from digikey this week and hopefully i can find time this weekend to dive in

wow - thank you for the amazing write up! such great notes - i feel better about attempting this myself now.Sure. On the Iwiss, you want to use the third from left section for AMP-UP contacts.

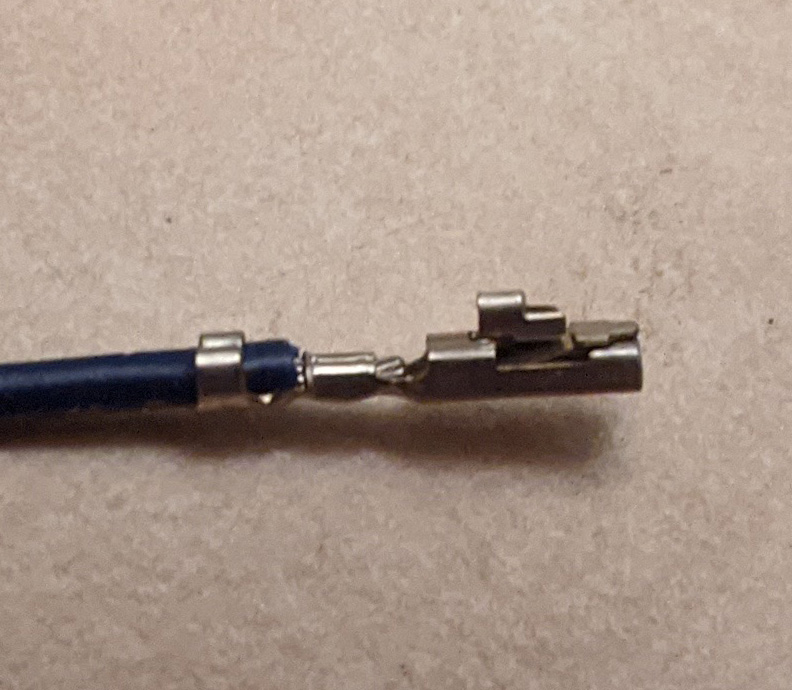

Make sure you position the contact as shown, so that the dividing line of the crimp surfaces is between the insulation and conductor crimp:

Close it to 3 clicks of the ratchet, so that it holds the contact steady, and make sure it's straight as shown:

Now you want to strip the wire so 3mm of conductor is showing and gently insert it with very little force. You will feel it stop naturally, this is the point where you close the tool fully. It takes some practice to get a feel, so try it a bunch on scrap wire.

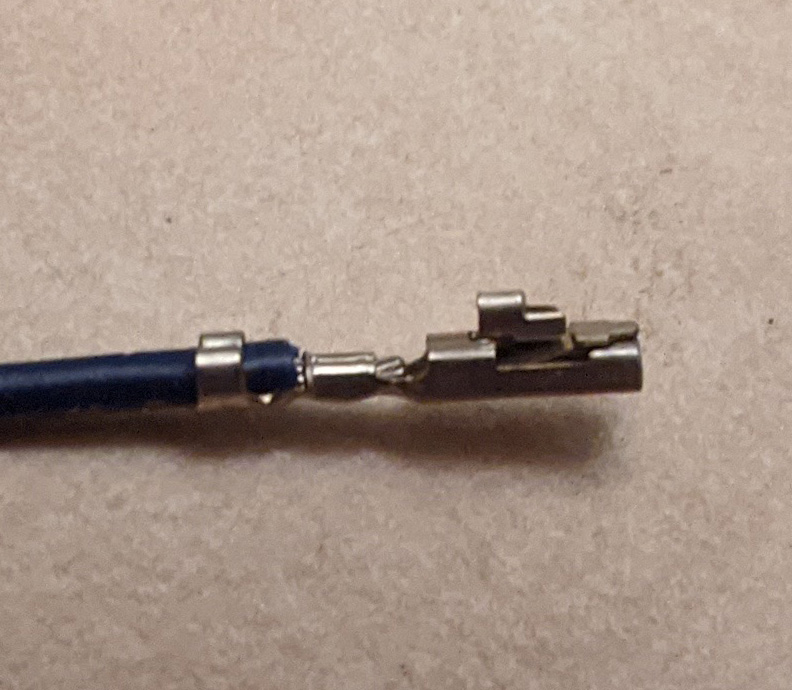

Here's a quick one I did to give you a general idea of what the Iwiss crimp is like, but mine is set a bit strong for this contact so it pierced the insulation. Play with the setting dial to try to reduce this, but it's not a big deal if it's a little pierced, very hard to get a perfect crimp with tools like this.

Here's an example of a BAD crimp. The main contact body is crushed. This is what happens if you ignore the first picture I posted:

Here's the UP contact crimped with the official tool, to give you an idea of what a "perfect" one looks like:

22AWG stranded UL1007wow - thank you for the amazing write up! such great notes - i feel better about attempting this myself now.

another newb question - what kind of wire do you recommend for making a harness?

22AWG stranded UL1007

The connectors in these pics are not the same ii will be using for the AMP UP I’m about to write up, right?Sure. On the Iwiss, you want to use the third from left section for AMP-UP contacts.

Make sure you position the contact as shown, so that the dividing line of the crimp surfaces is between the insulation and conductor crimp:

Close it to 3 clicks of the ratchet, so that it holds the contact steady, and make sure it's straight as shown:

Now you want to strip the wire so 3mm of conductor is showing and gently insert it with very little force. You will feel it stop naturally, this is the point where you close the tool fully. It takes some practice to get a feel, so try it a bunch on scrap wire.

Here's a quick one I did to give you a general idea of what the Iwiss crimp is like, but mine is set a bit strong for this contact so it pierced the insulation. Play with the setting dial to try to reduce this, but it's not a big deal if it's a little pierced, very hard to get a perfect crimp with tools like this.

Here's an example of a BAD crimp. The main contact body is crushed. This is what happens if you ignore the first picture I posted:

Here's the UP contact crimped with the official tool, to give you an idea of what a "perfect" one looks like:

Ok. Just to make sure I have everything correct. I have this Naomi harness:That looks like the correct crimp series, but wrong crimp gender. It gets a bit confusing...

The plastic connector body comes in both a Plug and Receptacle.

The crimp connectors come in both Pin and Socket.

You need to pair up the connector body Plug with crimp sockets.

You need to pair up the connector body Receptacle with crimp pins.

You have the crimp pins shown above, you need the crimp sockets (https://www.digikey.com/en/products/detail/te-connectivity-amp-connectors/175151-1/1152993)

Awesome. Glad to have the confirmation and doubly glad that I can start wiring this weekend!You have the correct contacts for your application. I just messed up and used the wrong gender in my example but everything will be exactly the same (on the official tool, both genders are crimped in the same place). And yes, make sure the right input goes to the right receptacle, don't rely on wire colors because sega and SNK used different colors, and there is no standard.

EDIT: You don't need to buy any female contacts because you have the premade harness. You are good with the contacts and housings you have.

Have fun, don't forget to make a bunch of practice crimps to make sure you have it down (assuming you bought plenty of contacts), and do a pull test on the practice ones (pull hard on the contact, it should not come off)Awesome. Glad to have the confirmation and doubly glad that I can start wiring this weekend!

I bought 50 crimps. Hopefully it’s enough to test and learn how to do it properly.Have fun, don't forget to make a bunch of practice crimps to make sure you have it down (assuming you bought plenty of contacts), and do a pull test on the practice ones (pull hard on the contact, it should not come off)

Yeah you just slide it in and it will click into place. top part of the contact facing the top part of the housing. If you need to remove one for whatever reason, use a straighened paperclip at the top of the contact from the front while you pull the cable out the back.I bought 50 crimps. Hopefully it’s enough to test and learn how to do it properly.

OncE I do crimp it properly, do i just slide it into the AMP connector? Any trick i should know about that?

It really doesn't matter. I'd just get a nice piece of plywood, spend the few extra bucks for the better one, will cut cleaner and look nicerIs there a recommendation for wood type for a PCB Mounting Board? My Candy 26 didn't come with one and I'd like to get one made to fit.

thanks. I figured as much but wanted to make sure!It really doesn't matter. I'd just get a nice piece of plywood, spend the few extra bucks for the better one, will cut cleaner and look nicer