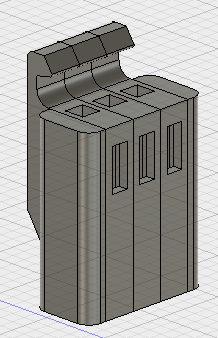

I'm not sure if I'm slightly leveled too close to the bed, but I ended up making the holes larger for the side that's on the print bed because they were coming out too small.

I press the nozzle right up against the bed for the first layer (I use a glass bed with spring mounts), this greatly helps with adhesion but I get some serious "elephants foot" on the first layer as a result. I typically compensate for this by adding a .4mm chamber along the parameter of everything that touches the bed, in effect this drops the outermost parameter from the bottom layer and the bottom edges come out perfect.

if you're running a brim for adhesion you could implement the chamfer on just the inside geometry (like the holes for the pins) and then use a

deburr tool to trim off the brim.

Certainly some connectors are subjected to heat and these have a lower melting point than some other plastics. I've encountered charred/melted housings in pinball machines. I'm not sure what those are made out of

I believe most electrical connectors are a nylon/polyester blend. they usually withstand temps up to 150-250C depending on the blend. The charred/melted connectors usually come from components failing and shorting which then causes all of the traces/wires/connectors completing the short to act like a giant resistor and since it's not actually a resistor it heats up and causes traces to burn up as well as connectors and wire jackets to melt.. which ever happens to be the weakest link.

You can print in Nylon, it's actually the best material for strength and temperature resistance, I've seen people print replacement gears for industrial applications using it. I've never tried but I hear it's an enormous pain in the ass to print with, you need really high temps (over 200C IIRC) and you tend to get a lot of warping and shrinkage that you need to accommodate for. I don't think you can get it colored either... just "natural" nylon.

I've done some printing with PETG, again you need some high temps for that (I think I'm using 145C nozzle temp, and no fan). it's got a rubbery feel to it and it's pretty strong, I'd argue its stronger than ABS in my experience, but when it fails it snaps like a kit-kat, at least when ABS fails it just bends and deforms and gets all chewy but it still holds together. I debated switching to PETG but I really don't like the surface finish, it's quite rough so for a lot of the stuff I'm making where the goal is to make it look nice, it really didn't work.

PLA is a lot stronger than most people give it credit for as long as you stay with a good brand, I've tested maybe a dozen brands of filament and a lot of them are straight garbage which is probably why PLA gets such a bad rap. For connectors though Nylon or PETG are probably your best bet and I say that not because of the strength but because they're going to need to flex and parts of them are going to be under pressure (when you consider the latches on the connectors use to mate), PLA doesn't like being under stress for long periods of time and it doesn't like flexing either, ABS is good to flex but again doesn't like being under stress. PETG and Nylon are both good with this though. I've printed fidget spinners and these little shark shaped clothes pins in ABS and after a few months all of them... 100% of them developed stress fractures. the shark pins because it uses the natural flexibility of the plastic as the "hinge" and developed the fractures on that area when it was left clamped to something for weeks, and the spinners had press-fit bearings and cracked from the stress of the bearing pushing outward. I had similar results with PLA, but it's expected with PLA.

I would guess that for those NH style connectors you're using, if printed in PLA or ABS the latching tab will eventually snap off on it's own accord if left plugged in for a few months, especially because this will stress right across the layer plane.

I'm seriously on like 4 or 5 different programs trying to do the things I want to accomplish for 3D printing. Pile on the extra stuff I use for my CNC machine and it's crazy!

I'm seriously on like 4 or 5 different programs trying to do the things I want to accomplish for 3D printing. Pile on the extra stuff I use for my CNC machine and it's crazy!