Helpful post with lots of info and recommended products, regarding cleaning PCBs: https://www.aussiearcade.com/forum/...-a-dishwasher-or-with-dish-washing-detergents

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Thread starter djsheep

- Start date

A

Apocalypse

I do that.

I just make sure to dry the PCBs quickly afterwards.

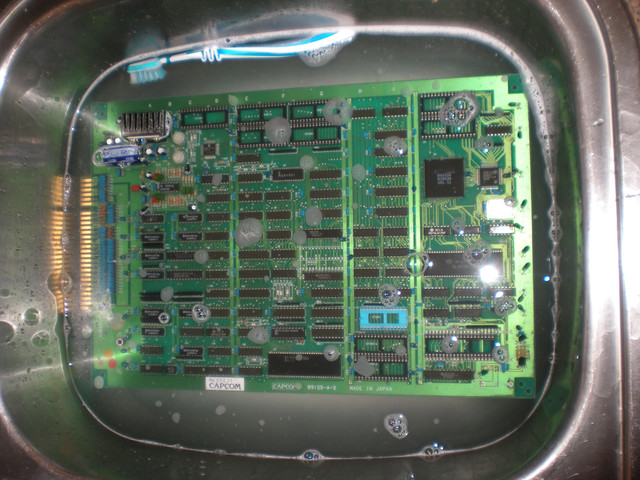

When boards are really too gross (e.g. covered in mouse pee) I wash them in the garage's sink:

I just make sure to dry the PCBs quickly afterwards.

When boards are really too gross (e.g. covered in mouse pee) I wash them in the garage's sink:

Last edited by a moderator:

Washing in a sink works fine too, done that multiple times. Just what Apocalypse said - dry quickly. After rinsing under warm/hot water I let most of the water run off freely from PCB few minutes and then pressure air for removing water under chips etc. Then I use a circulating air oven (normal kitchen thing nowadays) for about 15-30 minutes, 50-60C.

Raph_friend

Grand Master

I do it when needed.

Tonybolony

Professional

Am truly stunned you can do this lol v, you learn something new every dayI do it when needed.

I thought those were scanlines.I washed a monitor chassis once, it had rat droppings on it.

I've never washed any game PCB, ever. I own some dusty boards, but they all seem to run just fine?

I don't count dust as an issue which should be washed (I have some dusty boards too, they are all fine as is). Unless it's pinball dust... That contains metal and when layered enough, it gives you magical light & smoke show.

But when there is real dirt, mouse piss, WD40 all over, caps leakage, dried soda, whoeverknows?... It's time for a total cleanup, or at least partial (sometimes a corner only).

J

jassin000

I spray 'em off with IPA and then hit 'em with an air compressor to dry up any missed spots/droplets.

I'm fearful of using abrasives like a toothbrush to scrub, what if a bristle catches on a SMD IC foot and pops/rips it up?

I'm fearful of using abrasives like a toothbrush to scrub, what if a bristle catches on a SMD IC foot and pops/rips it up?

I also don't wash game PCB's. Most of the time isopropyl alcohol 91-99% and a medium soft paintbrush is the most I do.

I only wash CRT Chassis', they get super grimey.

I only wash CRT Chassis', they get super grimey.

I don't use a toothbrush, I use a medium soft paintbrush to scrub. The longer bristles are very bendable and soft that they don't damage anything, but also good enough to get your PCB's clean.I'm fearful of using abrasives like a toothbrush to scrub, what if a bristle catches on a SMD IC foot and pops/rips it up?

Like @nem says, don't wash PCBs. There is danger here and that is water ingress. So if you want to do it the professional way.

If you really want to wash your PCB and then dry it in the oven.

BTW:

This subject pops up again and again, use the new & improved search

If you really want to wash your PCB and then dry it in the oven.

- Pre-heat your oven to: 80C or 175F

- Insert your PCB using a suitable grid / shelf /suspension

- Leave it there for 2 hours

- After two hours, turn off the oven and let it cool down.

BTW:

This subject pops up again and again, use the new & improved search

J

jassin000

We do this at my work all the time, many different "ambient bakes" and "stable bakes" after deps and oxides etc.Pre-heat your oven to: 80C or 175F

The problem I'm seeing is in a basic/home kitchen, don't have the greatest of hoods/ventilation systems.

Aren't we getting some toxic release from components (even as low as 175f)?

I know GaAs (Gallium Arsenide) substrate produces some very nasty arcine (arsenic) gases, that IF you can smell 'em (they say its something like cherries) your ass is DEAD already.

clam_wattson

Student

I'm with you Mike, really gross to be putting something like that in a device meant to be cleaning your dishes. Another really important thing to consider is that most ovens are really terrible at maintaining low temperatures. They have to run their heating elements at a low duty cycle so you can get some really high temperature spikes - well above the 200 *F you might have set and expected it to maintain. This is something you all would know if you ever used your ovens for anything other than baking PCBs  .

.

.

.

A

Apocalypse

You don't have to be worried about it at all if you remember to dry boards up soon after. It's only a problem when parts are poorly designed and let humidity get in the chip case.There is danger here and that is water ingress.

Having your board 20/30mn in the dishwasher is still better than having it in ambient air in a country with a lot of humidity for 20 years.

Corrosion is a matter of exposition time.

We have a lot of boards dying in operation here in NZ because of the moist climate during winter.

Not sure who you're attacking here, I will answer for myself.Using the dishwasher is a moron method.

I obviously don't use the same dishwasher. The one for the PCBs stays in the garage. It's probably 20+ yo, but it cost me only NZ$50 (~30€) so I'm happy with it. Some plastic parts in the trays are broken but I don't care.I don't feel great about putting something full of lead solder in the same dishwasher as I'd use for dishes.

Surely being rude with others makes you a better person.Who made you that way?

That's why I'm using a lab oven I got for free when working in the pharmaceutical industry. It sits on top of the dishwasher.Another really important thing to consider is that most ovens are really terrible at maintaining low temperatures. They have to run their heating elements at a low duty cycle so you can get some really high temperature spikes - well above the 200 *F you might have set and expected it to maintain. This is something you all would know if you ever used your ovens for anything other than baking PCBs.

You can set temperature between 20 and 80°C.

Binder is the brand, for those interested, it's also useful if you're into handcrafting things, etc.

Luckily, the boards I’ve gotten have all been mostly free of grime. I usually only have to dust with soft anti-static brush and blow with compressed air Occasionally, I’ll use isopro alcohol for spot-cleaning.

My problem is getting rid of flux after replacing capacitors or light repair work. I use no-clean liquid flux and spray it down with IPA afterwards. Using IPA just moves the flux all over the board and dries leaving a sticky mess. I‘m hesitant to do a deeper wash using water or detergents.

Does anyone have an easy and simple way of cleaning off dried flux?

My problem is getting rid of flux after replacing capacitors or light repair work. I use no-clean liquid flux and spray it down with IPA afterwards. Using IPA just moves the flux all over the board and dries leaving a sticky mess. I‘m hesitant to do a deeper wash using water or detergents.

Does anyone have an easy and simple way of cleaning off dried flux?

Isopropyl alcohol.Does anyone have an easy and simple way of cleaning off dried flux?

I washed and dried hundreds of pcbs in the sun or on the radiator, never one broken !!!

He's washing some glass and plastic ..., it's important to make sure they dry thoroughly before turning them on.

What ruins pcbs is prolonged humidity over time, years and decades.

He's washing some glass and plastic ..., it's important to make sure they dry thoroughly before turning them on.

What ruins pcbs is prolonged humidity over time, years and decades.