IMHO the key is the size of the nozzle.

I had a Pro'skit SS-331H and it wasn't great as the smallest nozzle was 1.0mm. That's too big and would easily damage the pcb around the pin.

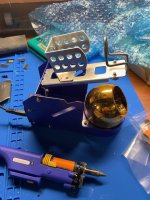

I swapped to a SP-1010DR (ZD-915) and bought a compatible 0.8mm nozzle. It is a dream!

1. Spend the extra 2 mins tinning the pins with a little extra solder

2. Desolder at 360 degrees holding against the pin for 1 second and it removes all solder with ease. The 0.8mm nozzle means the full circumference of the nozzle is touching all solder and no pcb for an instant melt.

3. Don't attempt to extract the component until giving the pins a quick blast with hot air at 320 degrees @ full air to guarantee any tiny solder remnants melt and the component will glide out with zero force and no damage.

I had a Pro'skit SS-331H and it wasn't great as the smallest nozzle was 1.0mm. That's too big and would easily damage the pcb around the pin.

I swapped to a SP-1010DR (ZD-915) and bought a compatible 0.8mm nozzle. It is a dream!

1. Spend the extra 2 mins tinning the pins with a little extra solder

2. Desolder at 360 degrees holding against the pin for 1 second and it removes all solder with ease. The 0.8mm nozzle means the full circumference of the nozzle is touching all solder and no pcb for an instant melt.

3. Don't attempt to extract the component until giving the pins a quick blast with hot air at 320 degrees @ full air to guarantee any tiny solder remnants melt and the component will glide out with zero force and no damage.

Last edited: