Be easy with some standoffs, you'd just need to put matching heat set inserts into the 3D print.Would love an acrylic top cover for this to match all my other PCB's with cases

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Thread starter ShootTheCore

- Start date

That's by Ranny Snice, file is here:Did you make that card at the top of the control panel with the MiSTer instructions?

https://drive.google.com/file/d/1c3Lip7y0m1iWuXIrhdmIAoWwYm6BhJ_4/view

Did you make that card with the MiSTer instructions at the top of the control panel?

Oooh that's a good idea! I'll need to see what that would take to do

@Derick2k up for the challenge? happy to fund a prototype material cost with acrylic haha.

Looks great!

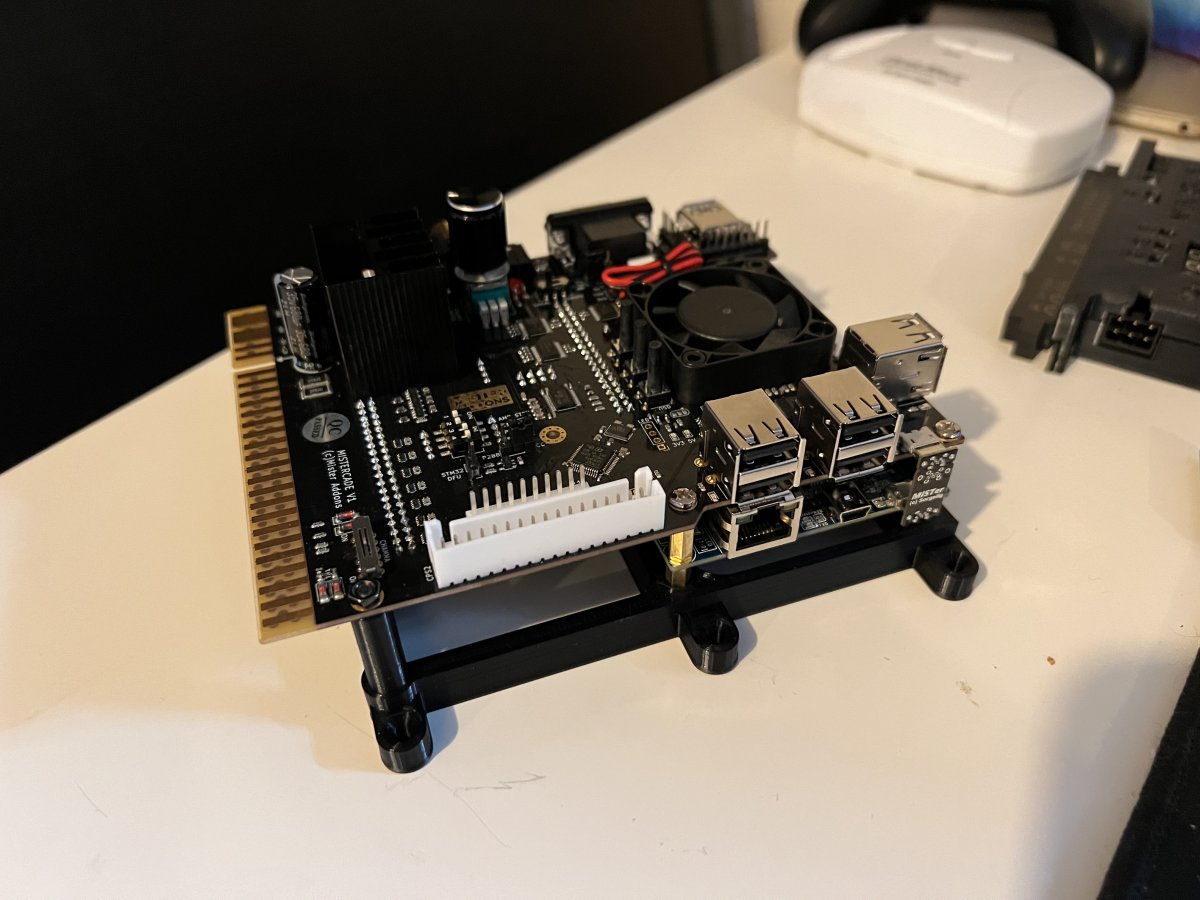

Second draft looks good! Feels very rigid. I’ll be heading to Home Depot today to grab some #4 screws and test attaching it to some plywood. As long as that goes ok, I’ll put it on thingiverse.

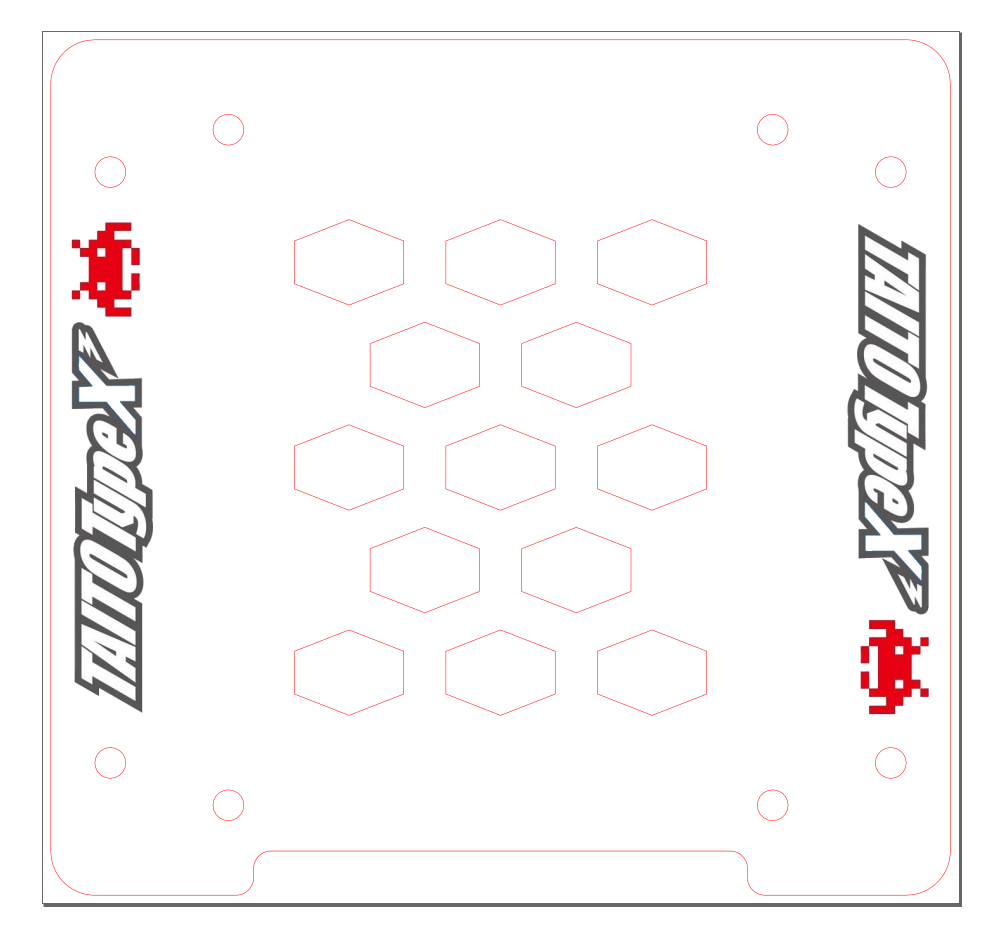

For sure, you want top and bottom covers? I can also do threaded inserts in the acrylic@Derick2k up for the challenge? happy to fund a prototype material cost with acrylic haha.

You want any logos/markings/cutouts, etc???

If you want to make a sketch of how you want it I can do some test cuts in 1/8, 1/4 acrylic, etc..

For sure, you want top and bottom covers? I can also do threaded inserts in the acrylic

You want any logos/markings/cutouts, etc???

If you want to make a sketch of how you want it I can do some test cuts in 1/8, 1/4 acrylic, etc..

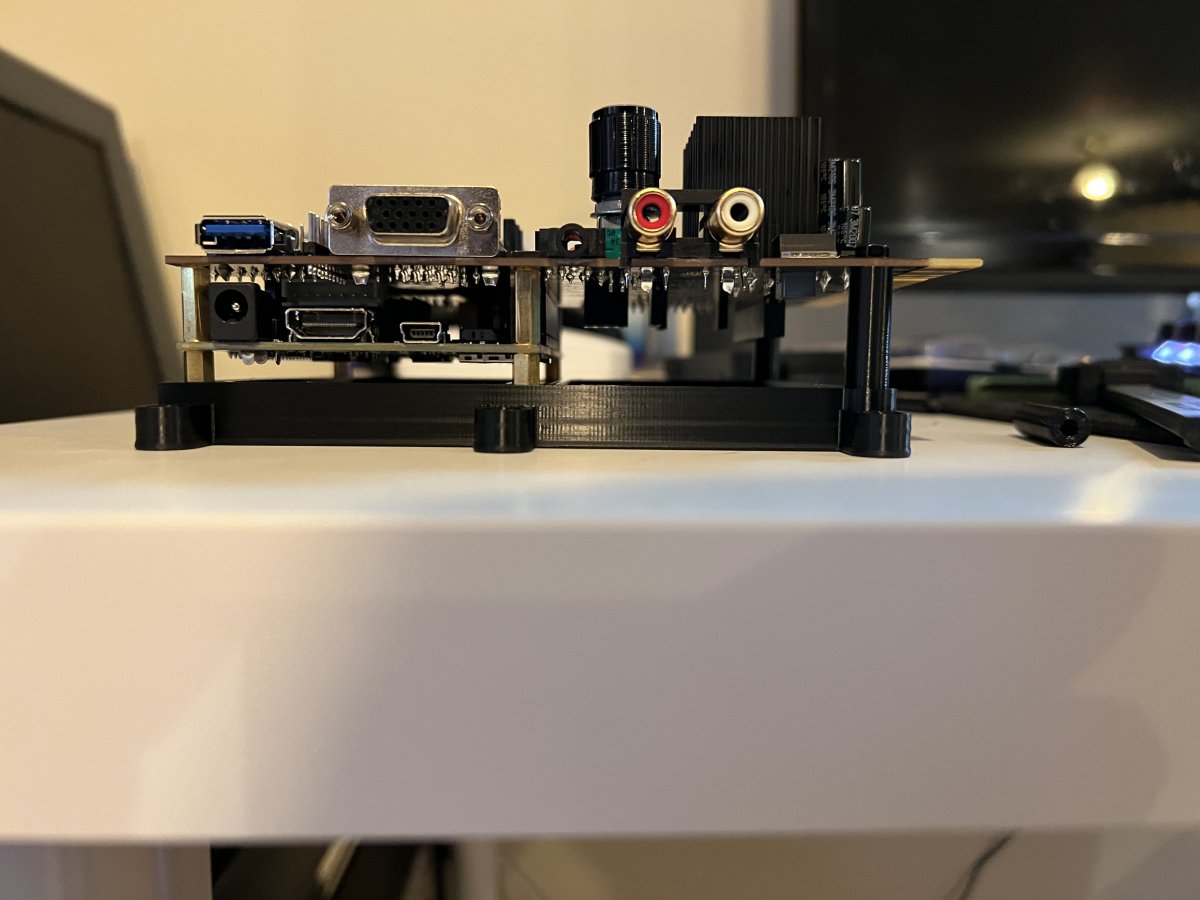

@TodoRojo you're up my dude! I imagine vents where the heatsink and fan are located. Personally a top cover would be enough. What do you all think?

Woo! LolFor sure, you want top and bottom covers? I can also do threaded inserts in the acrylic

You want any logos/markings/cutouts, etc???

If you want to make a sketch of how you want it I can do some test cuts in 1/8, 1/4 acrylic, etc..

I just ordered some heat set inserts and then I’ll adjust my model to utilize them for the front posts.

Top cover is just fine, I think! Vents for the fan and heat sink are great. The other thing to think about are the buttons just below the fan. We could print some buttons to rest on them and stick out of the acrylic or just leave a hole to stick a finger through. I prefer the button idea though.@TodoRojo you're up my dude! I imagine vents where the heatsink and fan are located. Personally a top cover would be enough. What do you all think?

How high should we put the acrylic? Just over the I/O shields?

Yes this is excellent! Will the sdram have enough clearance there?

ok got it, I will do vent for the fan, a cut out for the heatsink and kick harness, round cutour to match the volume knob

Make the plexi rest just above the fan I guess, and do round cutouts for 3d printed buttons?

Make the plexi rest just above the fan I guess, and do round cutouts for 3d printed buttons?

Yes this is excellent! Will the sdram have enough clearance there?

should clear considering how high the heatsink is. we can control height based on standoffs.

Nailed it. Buttons will be easy. I’ll just make a small rim on the bottom and they go in through the bottom of the acrylic (I think you get what I’m talking about).ok got it, I will do vent for the fan, a cut out for the heatsink and kick harness, round cutour to match the volume knob

Make the plexi rest just above the fan I guess, and do round cutouts for 3d printed buttons?

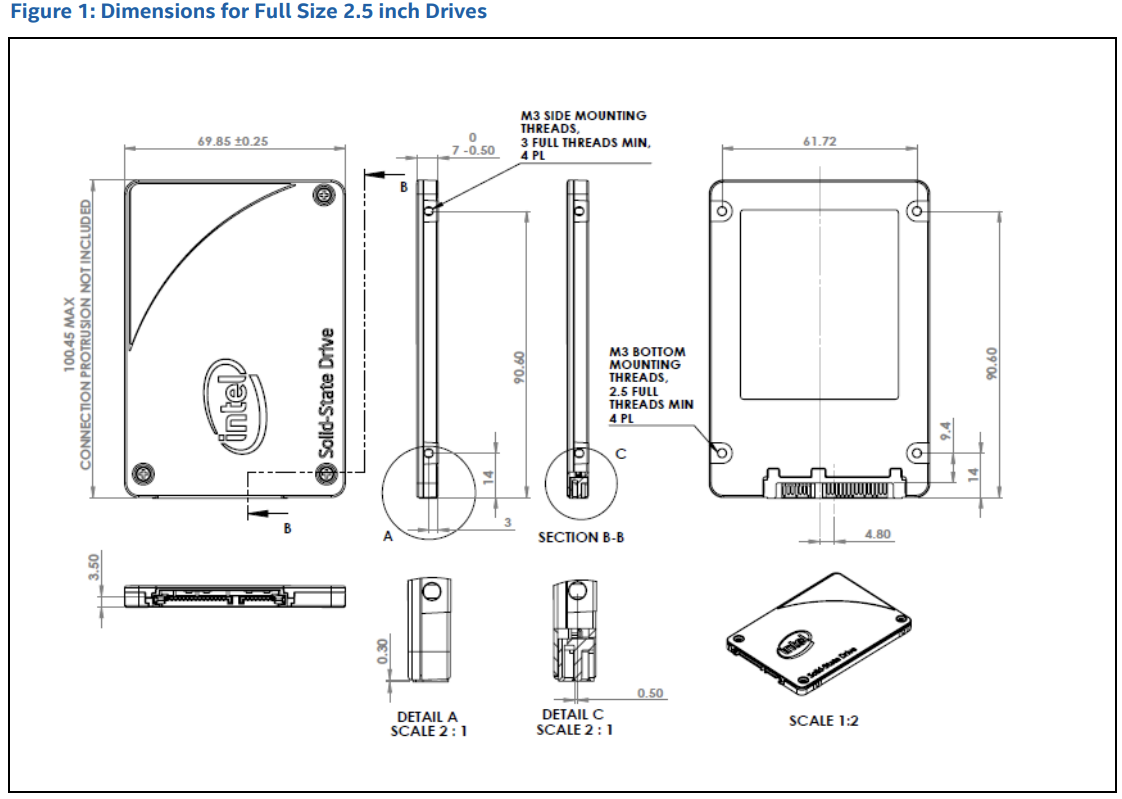

Could I ask: how do you get measurements for the cutouts? I was just using a digital caliper and lots of trial and error to find the distance between the mounting holes on the PCB. Any tips?

Unless the creator share the pcb layout files, I measure everything out on with digital calipers, input those into software and do a test cut on thick cardboard to make sure measurements line up.Nailed it. Buttons will be easy. I’ll just make a small rim on the bottom and they go in through the bottom of the acrylic (I think you get what I’m talking about).

Could I ask: how do you get measurements for the cutouts? I was just using a digital caliper and lots of trial and error to find the distance between the mounting holes on the PCB. Any tips?

The more you take measurements of stuff the better and faster you get at it, but on complex stuff I write/draw it out and calculate cutouts/spacing, etc ahead of time.

On common parts/devices I read the spec sheets to get the measurements, example I had to do a quick tray to mount a 2.5" ssd on my x3 that I swapped the coolre on with a taller one.

Used the measurements on the mechanical drawing

Sweet. Thank you. I wanted to make sure I wasn’t missing out on some cool hack haha. Near the end of my rope I just started 3d printing 3mm posts that would stick out and then measure from those. It did the trick ¯\_(ツ)_/¯.Unless the creator share the pcb layout files, I measure everything out on with digital calipers, input those into software and do a test cut on thick cardboard to make sure measurements line up.

The more you take measurements of stuff the better and faster you get at it, but on complex stuff I write/draw it out and calculate cutouts/spacing, etc ahead of time.

On common parts/devices I read the spec sheets to get the measurements, example I had to do a quick tray to mount a 2.5" ssd on my x3 that I swapped the coolre on with a taller one.

Used the measurements on the mechanical drawing

I think I need to print smaller components more often and do test fits like you do with the cardboard. Thanks for sharing those examples.

No real hacks that I can think of, unfortunately, There are tons of 3d scanning tools out there that can most likely do the job you want, not sure how fast it would be though or how good it would work.Sweet. Thank you. I wanted to make sure I wasn’t missing out on some cool hack haha. Near the end of my rope I just started 3d printing 3mm posts that would stick out and then measure from those. It did the trick ¯\_(ツ)_/¯.

I think I need to print smaller components more often and do test fits like you do with the cardboard. Thanks for sharing those examples.

ShootTheCore

Legendary

I believe another large batch will be available in early 2022.Any word on when more of these will be available?

I missed my chance on the first round.

Here's the link to the STL. This is the version that doesn't use heat-set inserts. I'll get that tooled tonight or tomorrow.

https://www.thingiverse.com/thing:5152714

Edit: As far as the height goes for the acrylic: I think 20mm would be enough to clear the IO, but the 680uf cap in front of the amp heat sink is 23mm. That could be included in the amp cutout, or we could sandwich some printed spacers between the acrylic and standoff. I'm sure there are other possibilities as well. Thoughts?

Edit 2: I’m hoping these edits aren’t blowing up people’s inboxes.

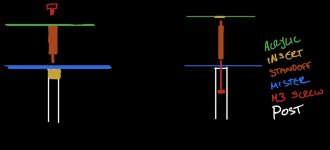

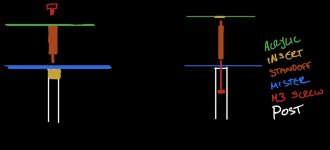

This is the image I have in my head, let me know if that’s what you’re thinking as well. We could also have no heat-sets at all. I would allow the screw to poke out more from the post and then use a pass-thru stand-off. ¯\_(ツ)_/¯

The heat-set version is uploaded to thingiverse

https://www.thingiverse.com/thing:5152714

Edit: As far as the height goes for the acrylic: I think 20mm would be enough to clear the IO, but the 680uf cap in front of the amp heat sink is 23mm. That could be included in the amp cutout, or we could sandwich some printed spacers between the acrylic and standoff. I'm sure there are other possibilities as well. Thoughts?

Edit 2: I’m hoping these edits aren’t blowing up people’s inboxes.

This is the image I have in my head, let me know if that’s what you’re thinking as well. We could also have no heat-sets at all. I would allow the screw to poke out more from the post and then use a pass-thru stand-off. ¯\_(ツ)_/¯

The heat-set version is uploaded to thingiverse

Last edited:

Whichever way works best for you guys, Im ok with.

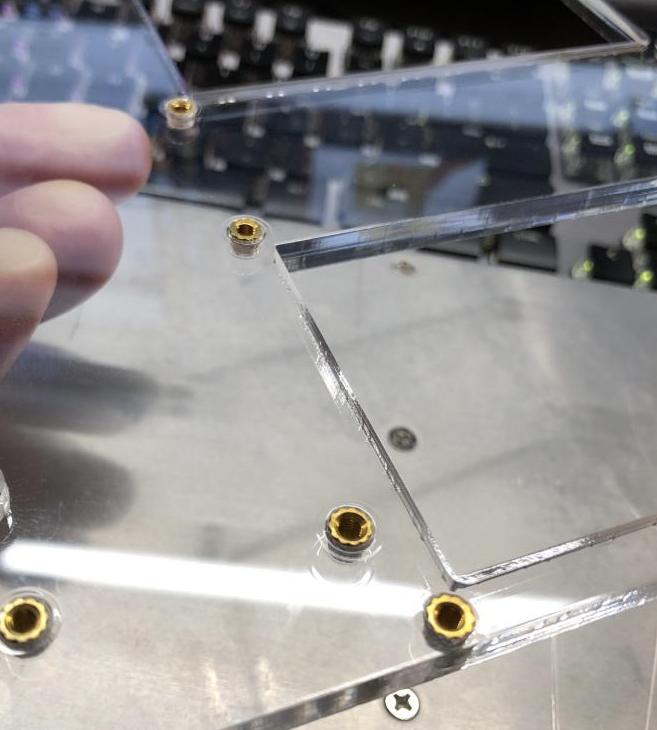

This is how heatset inserts work out in acrylic

and this is a test piece of that ssd mount plate I was working on earlier, this a rushed paint job, and I didnt clean the masking fully, was just trying to see if I like it before I commit to making more.

This is how heatset inserts work out in acrylic

and this is a test piece of that ssd mount plate I was working on earlier, this a rushed paint job, and I didnt clean the masking fully, was just trying to see if I like it before I commit to making more.