tiff_lee

Grand Master

Ok brains trust, looking for any ideas/feedback as how to best restore the friction mechanism for the punch pads.

I intend to knock up a project thread documenting this cab when i'm all done (currently trying some stuff out with other motors/gearboxes) but apart from the audible noise from the 573 (thread plug >> https://www.arcade-projects.com/thr...noise-once-game-has-booted-initialised.21279/ ) this mechanism is the last problem I don't have a solution for yet.

Ok picture time:-

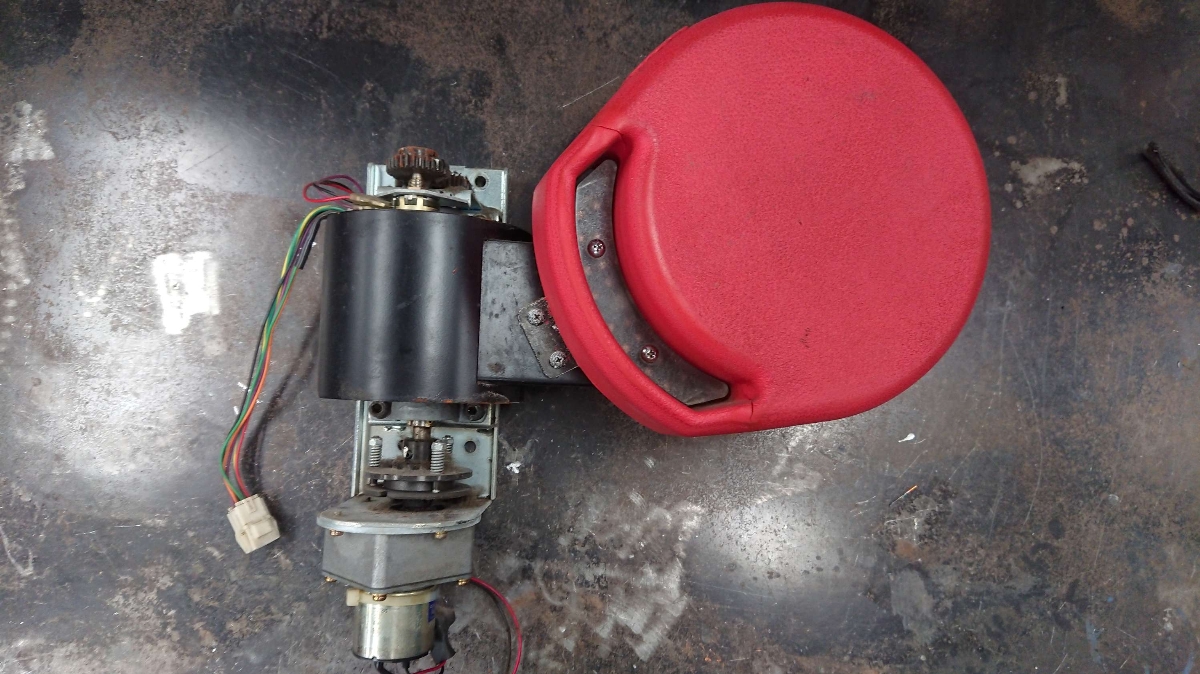

Here is one complete punch pad mechanism, motor, gearbox and pad. Not going too much into the motor/gearbox stuff as that will be covered later.

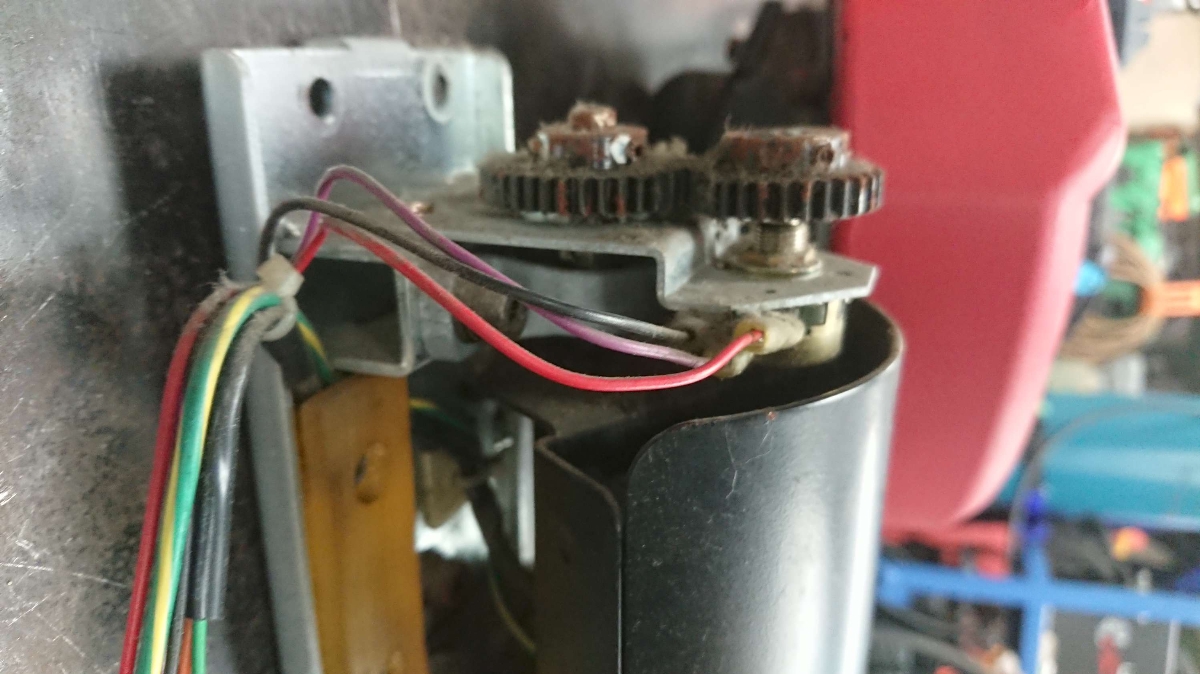

There is a potentiometer mounted on the top which is coupled to the pad via the two gear wheels. This provides pad position feedback via the security cart of all things.

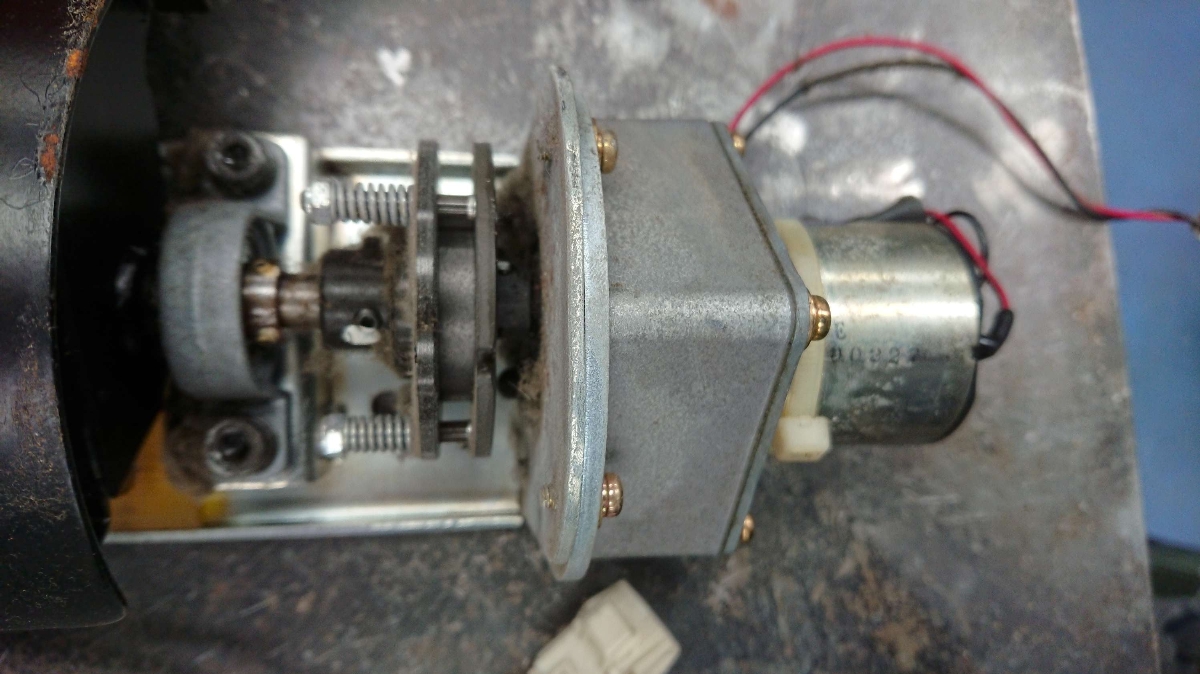

There is a small DC motor and reduction gearbox which has a square drive on the output shaft that interfaces with a carbon/graphite/<something> slip ring in-between the two metal faces. Tension is applied via the springs pulling the bottom face up towards the other.

So in order to drive the pads out the (motor/gearbox) carbon ring rotates and the friction between this and the metal plates cause them to also rotate thus moving the pad out.

When the pad is struck this force overcomes the friction and the metal plates slip on the carbon ring allowing the pad to go back in even if the carbon ring is still trying to drive them out.

Given what IMO is the low height of the machine the top pads are perfectly placed as if you were actually throwing a jab at someone, while the bottom pads are somewhat awkward to punch as I find myself punching down at an angle. This is actually reflected in the state of the friction mechanisms as the top pads have next to no friction and are very slow to move out (the notion being these have been subject to the most abuse) , the bottom ones operate pretty much perfectly and the middle pads are well, in the middle both physically and functionally.

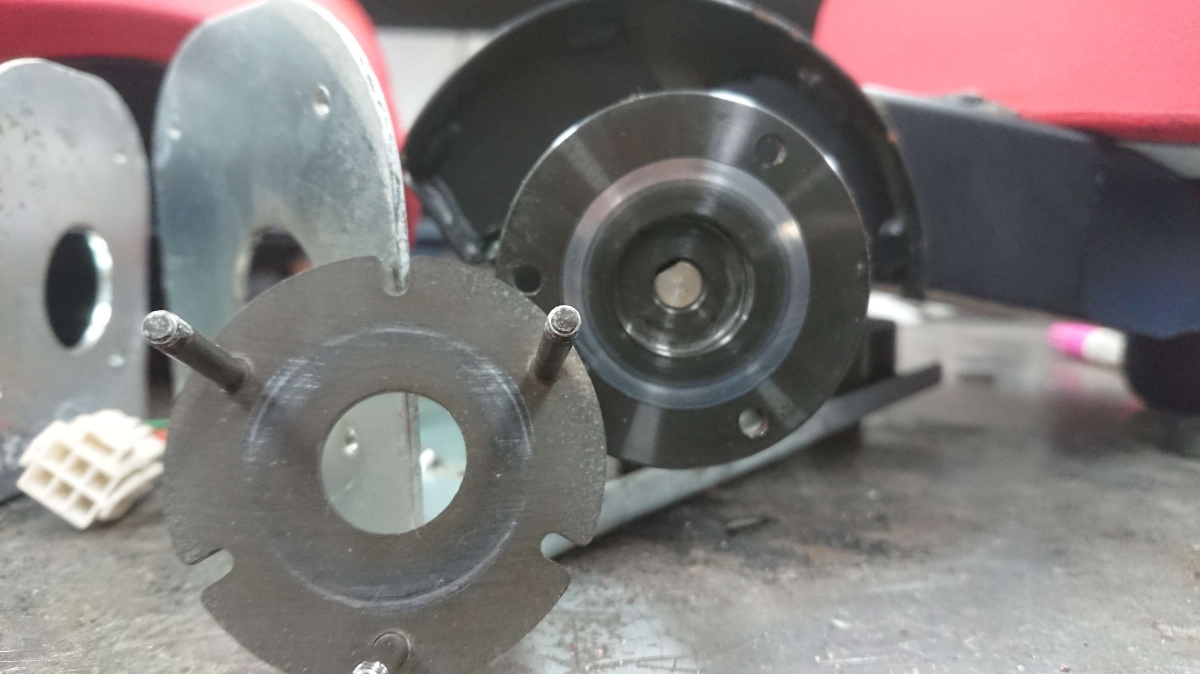

Friction plates of the top pad

Friction plates of the bottom pad

So while both worn you can clearly see there is more wear on the top mechanism than the bottom one and in operation it is certainly noticeable as the top pads are slow to respond (excessive slip due to the wear). When moving the pads by hand you can hear this in action, the bottom mechanism will actually all turn together (pad and gearbox) where as the top one just slips.

Quick vid here

View: https://www.youtube.com/watch?v=27QOUSAuFaA&ab_channel=lee3r24

I'm not sure what the finish on those plates actually is, some kind of electroplating?

The only real wear is the polished finished, there is no ridges or anything, however having them refaced isn't an issue (machining/blasting/sanding etc). For example, I was thinking of something along the lines of roughing the face up with say 600/800/<insert grade here> to remove that polished finish and then have the face re-plated (again no idea what with).

Curious to hear any other ideas, cheers.

I intend to knock up a project thread documenting this cab when i'm all done (currently trying some stuff out with other motors/gearboxes) but apart from the audible noise from the 573 (thread plug >> https://www.arcade-projects.com/thr...noise-once-game-has-booted-initialised.21279/ ) this mechanism is the last problem I don't have a solution for yet.

Ok picture time:-

Here is one complete punch pad mechanism, motor, gearbox and pad. Not going too much into the motor/gearbox stuff as that will be covered later.

There is a potentiometer mounted on the top which is coupled to the pad via the two gear wheels. This provides pad position feedback via the security cart of all things.

There is a small DC motor and reduction gearbox which has a square drive on the output shaft that interfaces with a carbon/graphite/<something> slip ring in-between the two metal faces. Tension is applied via the springs pulling the bottom face up towards the other.

So in order to drive the pads out the (motor/gearbox) carbon ring rotates and the friction between this and the metal plates cause them to also rotate thus moving the pad out.

When the pad is struck this force overcomes the friction and the metal plates slip on the carbon ring allowing the pad to go back in even if the carbon ring is still trying to drive them out.

Given what IMO is the low height of the machine the top pads are perfectly placed as if you were actually throwing a jab at someone, while the bottom pads are somewhat awkward to punch as I find myself punching down at an angle. This is actually reflected in the state of the friction mechanisms as the top pads have next to no friction and are very slow to move out (the notion being these have been subject to the most abuse) , the bottom ones operate pretty much perfectly and the middle pads are well, in the middle both physically and functionally.

Friction plates of the top pad

Friction plates of the bottom pad

So while both worn you can clearly see there is more wear on the top mechanism than the bottom one and in operation it is certainly noticeable as the top pads are slow to respond (excessive slip due to the wear). When moving the pads by hand you can hear this in action, the bottom mechanism will actually all turn together (pad and gearbox) where as the top one just slips.

Quick vid here

I'm not sure what the finish on those plates actually is, some kind of electroplating?

The only real wear is the polished finished, there is no ridges or anything, however having them refaced isn't an issue (machining/blasting/sanding etc). For example, I was thinking of something along the lines of roughing the face up with say 600/800/<insert grade here> to remove that polished finish and then have the face re-plated (again no idea what with).

Curious to hear any other ideas, cheers.

Last edited: