UPDATE:

files release official thread here: 3D Printed Sega ST-V Multi-Cart Housing

official thread here: 3D Printed Sega ST-V Multi-Cart Housing

--------

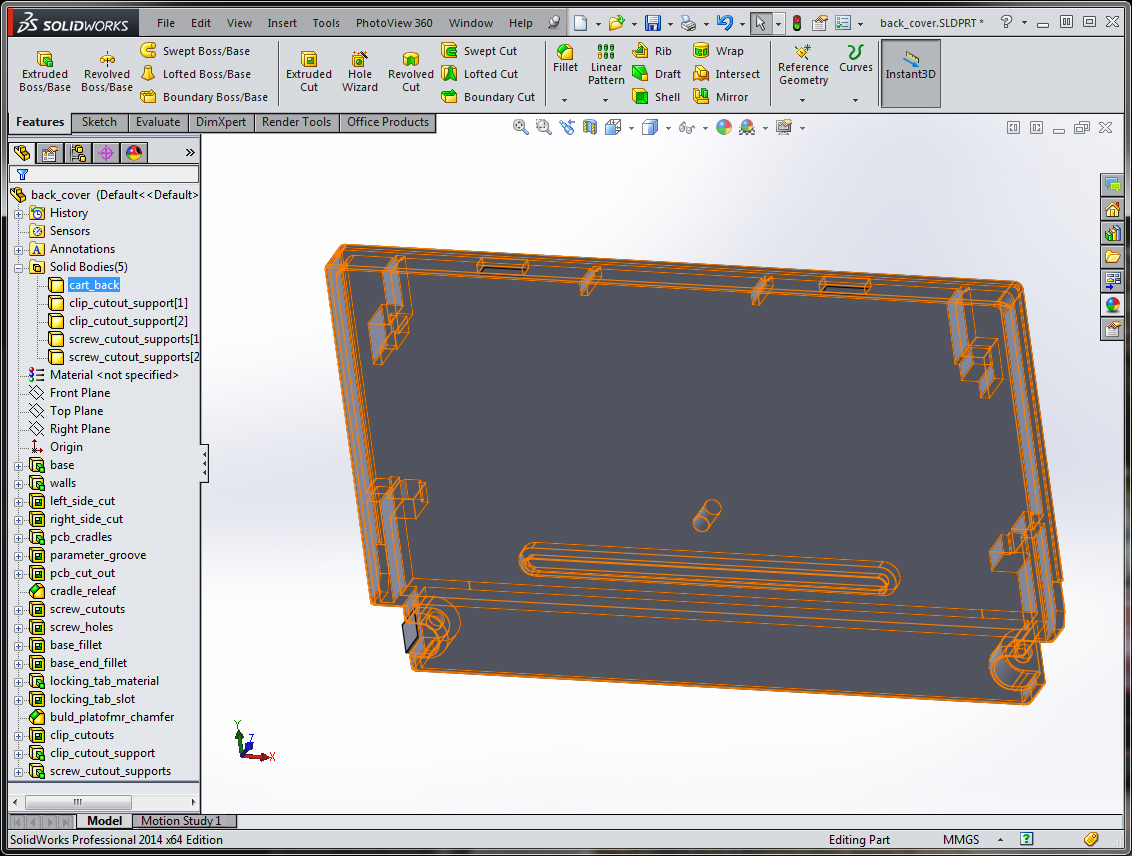

I started designing a 3D printable replacement cart housing for ST-V so we can use that instead of de-casing otherwise working games.

I've got the first revision of the back cover done so far (it's printing as I type this):

I'm creating a WIP thread here because there a a number of design decisions I'd like to get some feedback on.

1. The bulge in the front of the original cart. The ST-V main board, the ST-V multi, nor any of the original carts that I've seen need this. to print easily I need the front of the cart to be completely flat. Ideally I'd like to remove the hump along the bottom of the front and slim the whole cart housing down to a uniform size. I noticed that a lot of games have an empty EPROM socket in this area and if I remove the bulge then there likely wont be room for an EPROM here. I'm curious if anyone knows of any original cart PCBs that use this lot or any other game that might have something that takes up some of this extra space.

2. the game selection jumpers are kind of annoying I know there's the remote dip board that some people use. I managed to find this right angle dip set that I'm going to be using. de-soldering the pin headers that are there now and replacing with this dip-swich setup http://www.ebay.com/itm/DIP-Switch-...hash=item256cba9e38:m:mbnaJ8-pmENusm0lvbdI3Dw

To accommodate this I'll likely add a front cover with an optional hole in the top that is big enough to accommodate the original jumpers, dip switches, or the remote dip board. Are there other considerations I should be making here?

3. there's the reset pin, and the sound wire, I'm open to suggestions on the cleanest/simplest way to integrate these pins into the cart housing.

files release

official thread here: 3D Printed Sega ST-V Multi-Cart Housing

official thread here: 3D Printed Sega ST-V Multi-Cart Housing--------

I started designing a 3D printable replacement cart housing for ST-V so we can use that instead of de-casing otherwise working games.

I've got the first revision of the back cover done so far (it's printing as I type this):

I'm creating a WIP thread here because there a a number of design decisions I'd like to get some feedback on.

1. The bulge in the front of the original cart. The ST-V main board, the ST-V multi, nor any of the original carts that I've seen need this. to print easily I need the front of the cart to be completely flat. Ideally I'd like to remove the hump along the bottom of the front and slim the whole cart housing down to a uniform size. I noticed that a lot of games have an empty EPROM socket in this area and if I remove the bulge then there likely wont be room for an EPROM here. I'm curious if anyone knows of any original cart PCBs that use this lot or any other game that might have something that takes up some of this extra space.

2. the game selection jumpers are kind of annoying I know there's the remote dip board that some people use. I managed to find this right angle dip set that I'm going to be using. de-soldering the pin headers that are there now and replacing with this dip-swich setup http://www.ebay.com/itm/DIP-Switch-...hash=item256cba9e38:m:mbnaJ8-pmENusm0lvbdI3Dw

To accommodate this I'll likely add a front cover with an optional hole in the top that is big enough to accommodate the original jumpers, dip switches, or the remote dip board. Are there other considerations I should be making here?

3. there's the reset pin, and the sound wire, I'm open to suggestions on the cleanest/simplest way to integrate these pins into the cart housing.

Last edited: