You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Thread starter buffi

- Start date

PASTBLASTER

Grand Master

These printers look so awesome!

My next printer will probably be something similar to this one with multi extrusion, etc.

Congrats and can't wait to see what you make!

My next printer will probably be something similar to this one with multi extrusion, etc.

Congrats and can't wait to see what you make!

I picked up the P1P earlier this year. It has been a lot of fun.

I recently added the P1S enclosure. I struggled a bit with prints recently, not sure if it was the enclosure or the cold weather and high humidity lately but I think I have it dialed in now.

Bambu makes great products, very slick. I think the documentation and support is pretty bare bones though.

Since it’s right next to the cabs, I had to include them in the pic:

I recently added the P1S enclosure. I struggled a bit with prints recently, not sure if it was the enclosure or the cold weather and high humidity lately but I think I have it dialed in now.

Bambu makes great products, very slick. I think the documentation and support is pretty bare bones though.

Since it’s right next to the cabs, I had to include them in the pic:

I picked up a Bambu P1P during the Black Friday + TikTok sale and have been loving it. Not a single complaint so far!

Started teaching myself Fusion360 and published my first remix on Thingiverse recently, it’s an OSSC case for the cheaper Chinese model with a few changes from stock: https://www.thingiverse.com/thing:6435878

Shout out to ToddsNerdCave for the original OSSC case design.

Started teaching myself Fusion360 and published my first remix on Thingiverse recently, it’s an OSSC case for the cheaper Chinese model with a few changes from stock: https://www.thingiverse.com/thing:6435878

Shout out to ToddsNerdCave for the original OSSC case design.

plasticfactory

Grand Master

I've been happy with our Bambus. Currently running 6 of them.

Though, for the price point, I'd still prefer Prusa quit dragging their feet and get the XLs in user's hands.

Congrats on the buy -- if anyone needs a spare AMS, hit me up.

Though, for the price point, I'd still prefer Prusa quit dragging their feet and get the XLs in user's hands.

Congrats on the buy -- if anyone needs a spare AMS, hit me up.

Last edited:

I've only done some test prints so far, and quality and speed seems good... but...

...this sure makes more noise and vibrations than my old Ender 3 lol.

I mean I have this in my boiler room next to the water heater, and when it gets going it's still audible when closing the door to that room.

Not a huge deal, but I could see my wife getting annoyed by it since she has her desk in the room next to it, we'll see!

And I probably need to figure out a better table setup than the one I have it on now. Right now it's on a IKEA desk thats somewhat flimsy, and it will shake quite a bit.

Considering moving it to the floor for now until I figure something better out.

...this sure makes more noise and vibrations than my old Ender 3 lol.

I mean I have this in my boiler room next to the water heater, and when it gets going it's still audible when closing the door to that room.

Not a huge deal, but I could see my wife getting annoyed by it since she has her desk in the room next to it, we'll see!

And I probably need to figure out a better table setup than the one I have it on now. Right now it's on a IKEA desk thats somewhat flimsy, and it will shake quite a bit.

Considering moving it to the floor for now until I figure something better out.

plasticfactory

Grand Master

That looks like a nice setup. I definitely recommend some anti-vibration feet, it's a very cheap solution to assist with a number of problems.

I mean it did come on some sort of rubber feet. The table it stood on was very flimsy though, so this should be better. Planning to test it now!That looks like a nice setup. I definitely recommend some anti-vibration feet, it's a very cheap solution to assist with a number of problems.

edit: Less noise, good! Still sortof noisy, but this will work fine. Print quality turned out well as well!

Last edited:

I use a X1C with AMS at my work and I think it's a pretty decent printer so far in the 50-100 hours of print time I've used it. However, I personally prefer my MK3S with MMU2S so far for a variety of reasons (mostly maintenance related, but lots of small usability issues as well).

I had a Prusa XL on pre-order from day one, but ended up cancelling it when my turn came up a few months ago since it seems largely unfinished, even after the extremely long delay. Not great considering the very high (though not necessarily unjustified) price point. I hope they eventually get that printer in order since multiple toolheads for changing filaments is definitely the way I want to go, instead of the filament unload/reload system of the AMS and MMU.

I had a Prusa XL on pre-order from day one, but ended up cancelling it when my turn came up a few months ago since it seems largely unfinished, even after the extremely long delay. Not great considering the very high (though not necessarily unjustified) price point. I hope they eventually get that printer in order since multiple toolheads for changing filaments is definitely the way I want to go, instead of the filament unload/reload system of the AMS and MMU.

Really? I rarely use my MK3S anymore, my X1C is so much better and faster. It's handy to have multiple printers, aside from my Bambu and Prusa I have a Uniformation GKTWO, and there are times when I'll have all three going at once. But my Prusa is strictly a backup printer now.I use a X1C with AMS at my work and I think it's a pretty decent printer so far in the 50-100 hours of print time I've used it. However, I personally prefer my MK3S with MMU2S so far for a variety of reasons (mostly maintenance related, but lots of small usability issues as well).

I haven't even used my AMS for a multi-material print yet, haven't had a need, but just for being able to stock filaments I use often and easily switch between them (or use the auto switch over when a spool runs out) has been really handy. Worth having just for that.

I also can't imagine going back to a non-enclosed printer now. I'm printing mostly ABS, it's so much better than PLA for a lot of my use cases. What I really can't see buying much more of is PETG. Either PLA gets it done, or I go ABS. PETG is like the worst option comparatively. Not as heat resistant or easy to post process as ABS, harder to print and get consistent quality compared to PLA.

My Prusa lives inside in my office, so it is handy for quick little prints. Everything else is in the garage where I have a ventilation system connected for fumes from ABS and resin.

Like I said, the printer is decent, or even quite good. I still prefer my Prusa, but it's largely personal preference. I'll go a bit into the nitty gritty on this.

I dislike the slicer and how it's basically a Prusa Slicer clone but even more unintuitive. The printer also heavily relies on QR codes for troubleshooting. I also don't like how it pushes you to make an online account to print GCODE, and I don't like using MicroSD cards to print if I choose the go that route. The "lidar" sensor (it's not really lidar) feels like a gimmick, and the lack of a PEI sheet is borderline unacceptable to me. Going back to glue stick feels like I time traveled to 2017. The default startup process for each print takes forever and requires adjustment in the Start GCODE or EVERY print starts with resonance compensation, flow calibration and 1st layer check. I personally would've gone with the P1 series which side steps a few of these issues, but that sadly wasn't my call... Even though I end up being the guy that maintains the printer in my firm >.>'

The speed is nice, but my personal experiences shows that it has a noticeable effect on surface detail and finish and has a substantial effect on layer adhesion/strength. The speed also makes the printer very loud. Easily the noisiest one I work with. I'm sure I can tune most of not all of those issues out since the majority of printing quality is derived from slicer settings nowadays, but I won't be spending that time and effort to do so, especially on a printer that isn't mine. I may seem picky about this, but I print 1/16th and 1/8th inch scale architectural models, and the surface finish is my #1 concern, so this might just be a me-specific issue.

The AMS is nice when it works, but if filament snaps, especially in the internal PTFE hub connector, it's an annoying process to take the entire thing apart and hunt down the problem in comparison to the MMU2S. I've seen some nightmares regarding the rewinding mechanism online, but I haven't experienced them myself, so I like that a lot so far. Much better than the annoying spring-based spool holder + Repbox setup that I use with my MMU2S.

I'm undecided on the hotend setup so far. It seems reasonably reliable, but I haven't had the need to take it apart yet, so I don't have an opinion on it until that day comes.

I dislike the slicer and how it's basically a Prusa Slicer clone but even more unintuitive. The printer also heavily relies on QR codes for troubleshooting. I also don't like how it pushes you to make an online account to print GCODE, and I don't like using MicroSD cards to print if I choose the go that route. The "lidar" sensor (it's not really lidar) feels like a gimmick, and the lack of a PEI sheet is borderline unacceptable to me. Going back to glue stick feels like I time traveled to 2017. The default startup process for each print takes forever and requires adjustment in the Start GCODE or EVERY print starts with resonance compensation, flow calibration and 1st layer check. I personally would've gone with the P1 series which side steps a few of these issues, but that sadly wasn't my call... Even though I end up being the guy that maintains the printer in my firm >.>'

The speed is nice, but my personal experiences shows that it has a noticeable effect on surface detail and finish and has a substantial effect on layer adhesion/strength. The speed also makes the printer very loud. Easily the noisiest one I work with. I'm sure I can tune most of not all of those issues out since the majority of printing quality is derived from slicer settings nowadays, but I won't be spending that time and effort to do so, especially on a printer that isn't mine. I may seem picky about this, but I print 1/16th and 1/8th inch scale architectural models, and the surface finish is my #1 concern, so this might just be a me-specific issue.

The AMS is nice when it works, but if filament snaps, especially in the internal PTFE hub connector, it's an annoying process to take the entire thing apart and hunt down the problem in comparison to the MMU2S. I've seen some nightmares regarding the rewinding mechanism online, but I haven't experienced them myself, so I like that a lot so far. Much better than the annoying spring-based spool holder + Repbox setup that I use with my MMU2S.

I'm undecided on the hotend setup so far. It seems reasonably reliable, but I haven't had the need to take it apart yet, so I don't have an opinion on it until that day comes.

There is the option for LAN mode if you don't want to use the cloud service or SD cards. And there is also a PEI buildplate available as well. It comes standard with the P1S, not to mention all of the aftermarket buildplate options.I dislike the slicer and how it's basically a Prusa Slicer clone but even more unintuitive. The printer also heavily relies on QR codes for troubleshooting. I also don't like how it pushes you to make an online account to print GCODE, and I don't like using MicroSD cards to print if I choose the go that route. The "lidar" sensor (it's not really lidar) feels like a gimmick, and the lack of a PEI sheet is borderline unacceptable to me. Going back to glue stick feels like I time traveled to 2017. The default startup process for each print takes forever and requires adjustment in the Start GCODE or EVERY print starts with resonance compensation, flow calibration and 1st layer check. I personally would've gone with the P1 series which side steps a few of these issues, but that sadly wasn't my call... Even though I end up being the guy that maintains the printer in my firm >.>'

I'm well aware that most issues are addressable. It's death by a thousand cuts for me in terms of the myriad of things that I don't like, and that's on top of the fact that while I use the X1C fairly often in my firm, I don't actually own it, so I'm reluctant to do or buy things for it in the same way as if it were my own.

I'll emphasize again that it's a good, if not great printer overall. My gripes are largely personal preference related. I mention this because I know the discourse around printer brands (particularly Prusa vs Bambu) becomes toxic and tribalism based very quickly, although I highly doubt that would be much of a problem here at least.

I'll emphasize again that it's a good, if not great printer overall. My gripes are largely personal preference related. I mention this because I know the discourse around printer brands (particularly Prusa vs Bambu) becomes toxic and tribalism based very quickly, although I highly doubt that would be much of a problem here at least.

The P1S i bought comes with PEI stock, and I agree that its basically mandatory.and the lack of a PEI sheet is borderline unacceptable to me

I can se not liking the heavy focus on online connected apps but hey, it works well!

MK3S lack of enclosure sortof makes it a non-option for me. Thats one of the things I really wanted (in addition to more speed) when upgrading from my ender3

Last edited:

Btw, this happened to me pretty quickly when using some old filament where I (like an idiot) didnt clip off some damage to start of it from Ender3 extruder, and taking off and apart the AMS took like 5-10minutes, so not agreeing with this.The AMS is nice when it works, but if filament snaps, especially in the internal PTFE hub connector

Disconnect back connector and tube. Lift it off. Lift out spools (can still be connected to AMS even). Remove two screws. Lift internal parts of AMS and remove cable. Locate and remove filament from feeder tube. Put together.

Even having barely used that thing, this took very little time, and now that I’ve done it once, I could probably speedrun that shit in like 3 minutes.

In comparison to the MMU2S, it's way slower (granted, getting that cursed thing to a reliable state in the first place is an adventure).

I'm glad it doesn't take you long to fix the issues, but from my perspective I find the process of getting to the AMS to be very annoying for something that WILL happen on a somewhat regular basis unless you keep a constant supply of fairly fresh filament. On top of that, all of the screws to get there are self tapping instead of having threaded inserts IIRC, which is a pet peeve of mine. I don't want to take all my filament rolls out, lift the big plastic tub thing a specific way while remembering not to yank the 2 small connectors, then going on a hunt in the PTFE hub for the snapped filament every time it happens. I had an unfortunate case where the filament snap was tiny piece buried deep inside the internal hub, which required me to take that out, and totally disassemble it in order to get to that piece. I'm probably still feeling a bit salty about that.

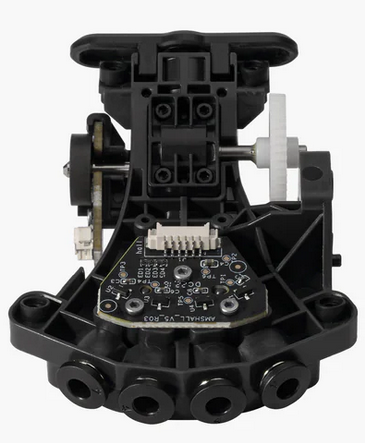

For reference in case it happens to anyone else, the tiny filament piece I mentioned was broken inside this part. It threw me for a loop when I couldn't see the broken filament piece and the AMS kept throwing and error after me taking it apart and searching over and over again.

I really wish for a reliable multi toolhead solution. I feel like a lot of my complaints would be mitigated or solved from that. Sadly the Prusa XL doesn't seem to be good enough (yet?)

I'm glad it doesn't take you long to fix the issues, but from my perspective I find the process of getting to the AMS to be very annoying for something that WILL happen on a somewhat regular basis unless you keep a constant supply of fairly fresh filament. On top of that, all of the screws to get there are self tapping instead of having threaded inserts IIRC, which is a pet peeve of mine. I don't want to take all my filament rolls out, lift the big plastic tub thing a specific way while remembering not to yank the 2 small connectors, then going on a hunt in the PTFE hub for the snapped filament every time it happens. I had an unfortunate case where the filament snap was tiny piece buried deep inside the internal hub, which required me to take that out, and totally disassemble it in order to get to that piece. I'm probably still feeling a bit salty about that.

For reference in case it happens to anyone else, the tiny filament piece I mentioned was broken inside this part. It threw me for a loop when I couldn't see the broken filament piece and the AMS kept throwing and error after me taking it apart and searching over and over again.

I really wish for a reliable multi toolhead solution. I feel like a lot of my complaints would be mitigated or solved from that. Sadly the Prusa XL doesn't seem to be good enough (yet?)

Last edited:

I picked up my first 3D printer not long ago, a Bambu A1. Couldn't rationalize the enclosed printers, and figured I'd get the AMS Lite later... But since getting into this and discovering the hazards of humidity, I'm disappointed there's no way to encluse the AMS Lite effectively. So I sort of wish I did splurge on the larger units.

Still, for the price, I'm very happy. It's wicked fast and much, much quieter than the Cocoon (thanks AldI) I'd borrowed before taking the plunge.

Still, for the price, I'm very happy. It's wicked fast and much, much quieter than the Cocoon (thanks AldI) I'd borrowed before taking the plunge.

Honestly, humidity has never really been an issue for me with PLA.

PETG however is very awkward to deal with unless dried first. Being able to print ABS instead now should be a lot nicer, but I havent bought any yet.

Should probably upgrade my ventilation as well, even if the P1S has filters installed

PETG however is very awkward to deal with unless dried first. Being able to print ABS instead now should be a lot nicer, but I havent bought any yet.

Should probably upgrade my ventilation as well, even if the P1S has filters installed