AlxUnderBase

Enlightened

Hi Alex,

Thanks for your reply.

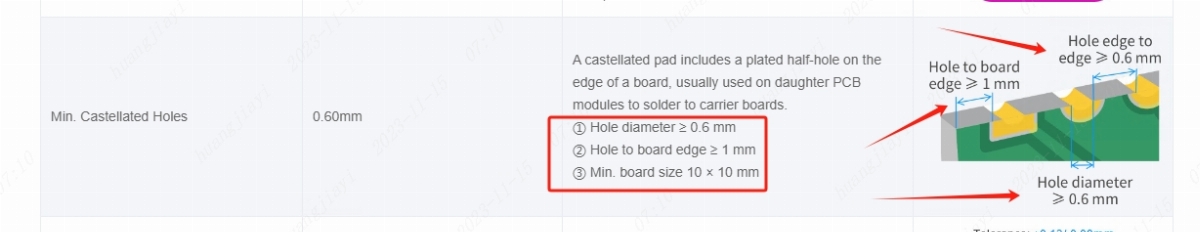

To proceed with castellated holes processing, you will need to modify your Gerber files to meet the requirements shown in the below image, and there will be around 35USD extra cost per order. Shall we activate replace file button for you to modify your files and send you extra cost to pay?

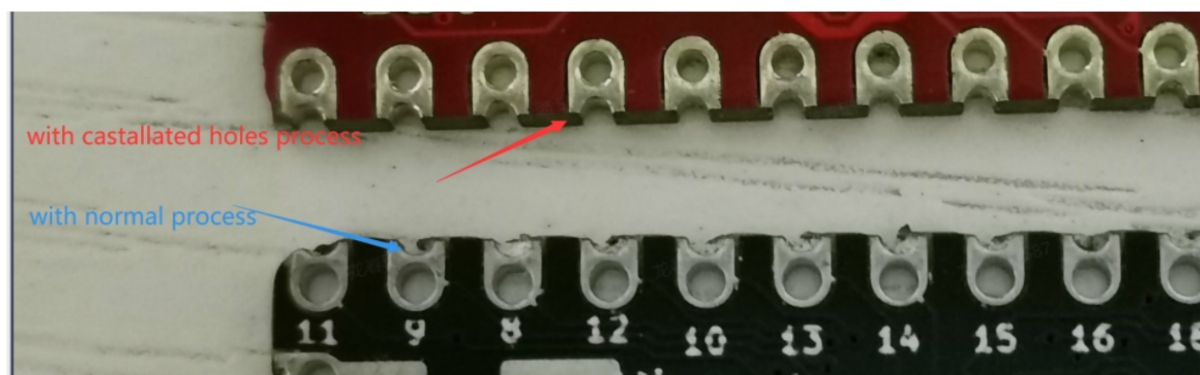

Or should we proceed with normal process with the risk of possible defects? Please kindly advise.

Best regards

Olivia

i know @ManCloud received same answer about manufacturing , but maybe this can help for the future .

I proceed on JLCPCB to normal process (like how the zip is on github)

This is for guys who wants castellated 0.8mm thickness for 161 in 1 daughter boards to be manufactured, with 35$ usd additional cost - 5 x double daughter boards =>

so the price can be 42 : 5 = 8.4$ USD