Have been working on a simple PCB that shrinks the footprint of traditional test benches like this:

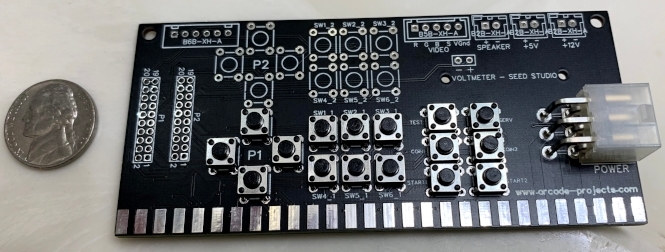

Down to something like this (an early prototype):

The problem of a traditional workbench is two-fold:

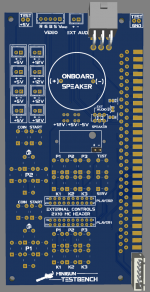

By keeping the testbench footprint small, perhaps this allows for portability. "Consolizing" this into a briefcase and testing PCB's out the field becomes a possibility. Ultimately, I will end up with this:

+

+

I toyed with the idea of using a Pico PSU, but with the power brick, it does not reduce the footprint from replacing the switching PSU. The last thing to do is to figure out which onboard speaker to use which will require moving some things around in the layout. Any other feedback is welcomed.

Consolidating the discussion that I've had with several people on the subject across different threads into this one. So paging a few folks: @ic3b4ll, @xodaraP, @pacoarcade, @ekorz,@'Frank_fjs',

Down to something like this (an early prototype):

The problem of a traditional workbench is two-fold:

- The footprint as a result of the JAMMA harness wiring and the footprint needed for controls.

- All the while, there is a need to make things elegant and clean for controls. Which can make costs go up.

By keeping the testbench footprint small, perhaps this allows for portability. "Consolizing" this into a briefcase and testing PCB's out the field becomes a possibility. Ultimately, I will end up with this:

I toyed with the idea of using a Pico PSU, but with the power brick, it does not reduce the footprint from replacing the switching PSU. The last thing to do is to figure out which onboard speaker to use which will require moving some things around in the layout. Any other feedback is welcomed.

Consolidating the discussion that I've had with several people on the subject across different threads into this one. So paging a few folks: @ic3b4ll, @xodaraP, @pacoarcade, @ekorz,@'Frank_fjs',

Attachments

Last edited: