Thomas

Professional

ネットシティSD(シットダウンタイプ)

It's been a year and a half since I received a trio of Cities from KC and I'm finally getting work done on the third and final City, the Net City. I have always liked the look of the Naomi/Net City series of cabinets so it was at the top of my list when cabinet shopping. Plus I wanted one cabinet with JVS support. The tri-sync monitor is cool too. I specifically requested an Old Net City instead of a New Net City only because I prefer the orange stylings. I had no idea that the New Net City has a superior monitor.

Here's what I got:

The guy making the delivery had a pickup with a small hydraulic lift cart that wasn't working. So we had to lift the cabinets out of the truck. The Astro and Blast went down okay. The Net has some extra weight and an awkward shape so it didn't come off the tailgate too smoothly. It took a hit to the back on the way down. Fortunately nothing looked damaged and the plastic monitor cover absorbed the impact.

I repeatedly requested and reminded KC to include a marquee holder and luckily he sent one. It wasn't attached to the cabinet when it arrived and I had to ask the delivery guy before he drove off to look for it under some stuff in the back of his truck and he found it. I had to be persistent to get that marquee holder and I'm glad to have it.

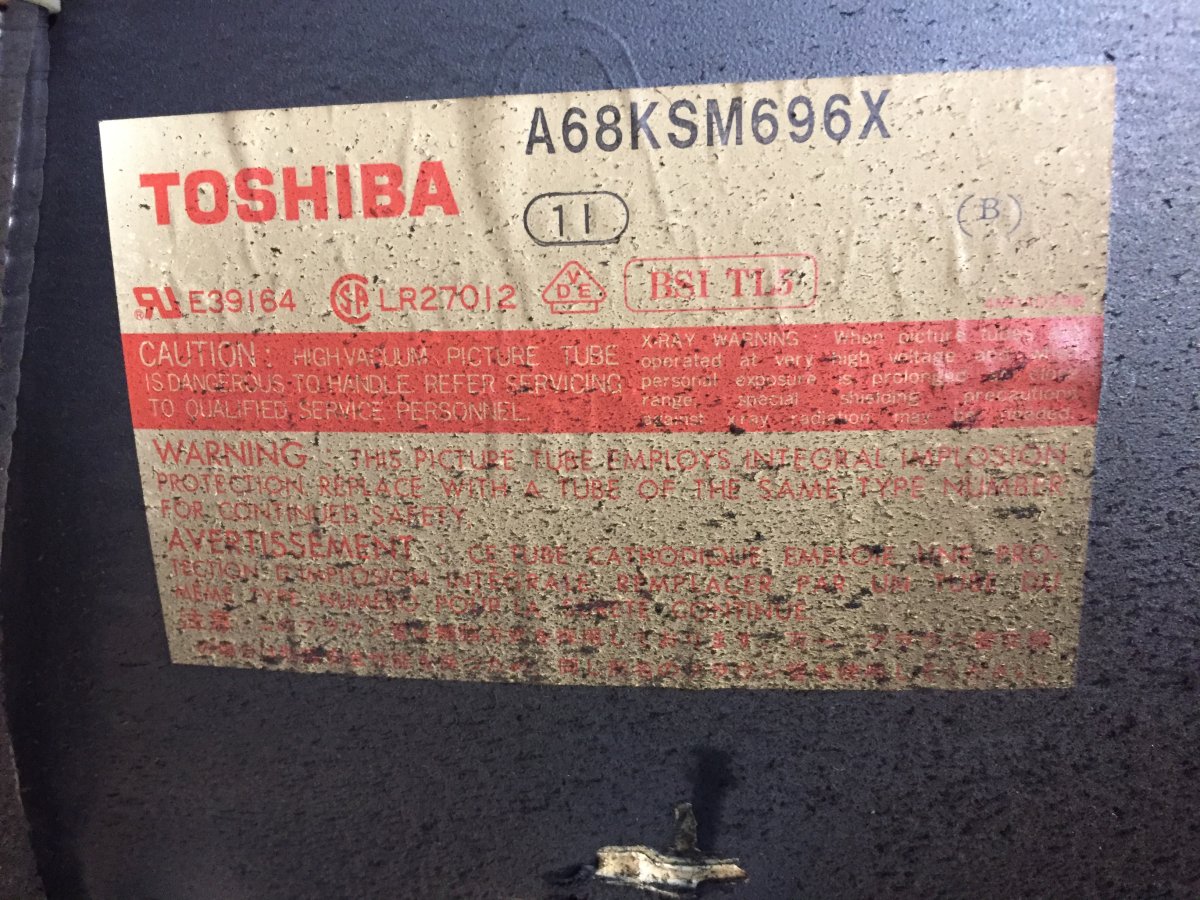

I disassembled and cleaned everything a full year ago and the parts have been all sitting in a pile since. Restoring the Astro and Blast Cities took a long time and I didn't want to deal with the Net until those were done. I did a quick test with a Dreamcast on the day the cabinet arrived just to make sure the monitor worked and that was it. I saw some convergence problems in the corners of the screen but otherwise the picture looked okay.

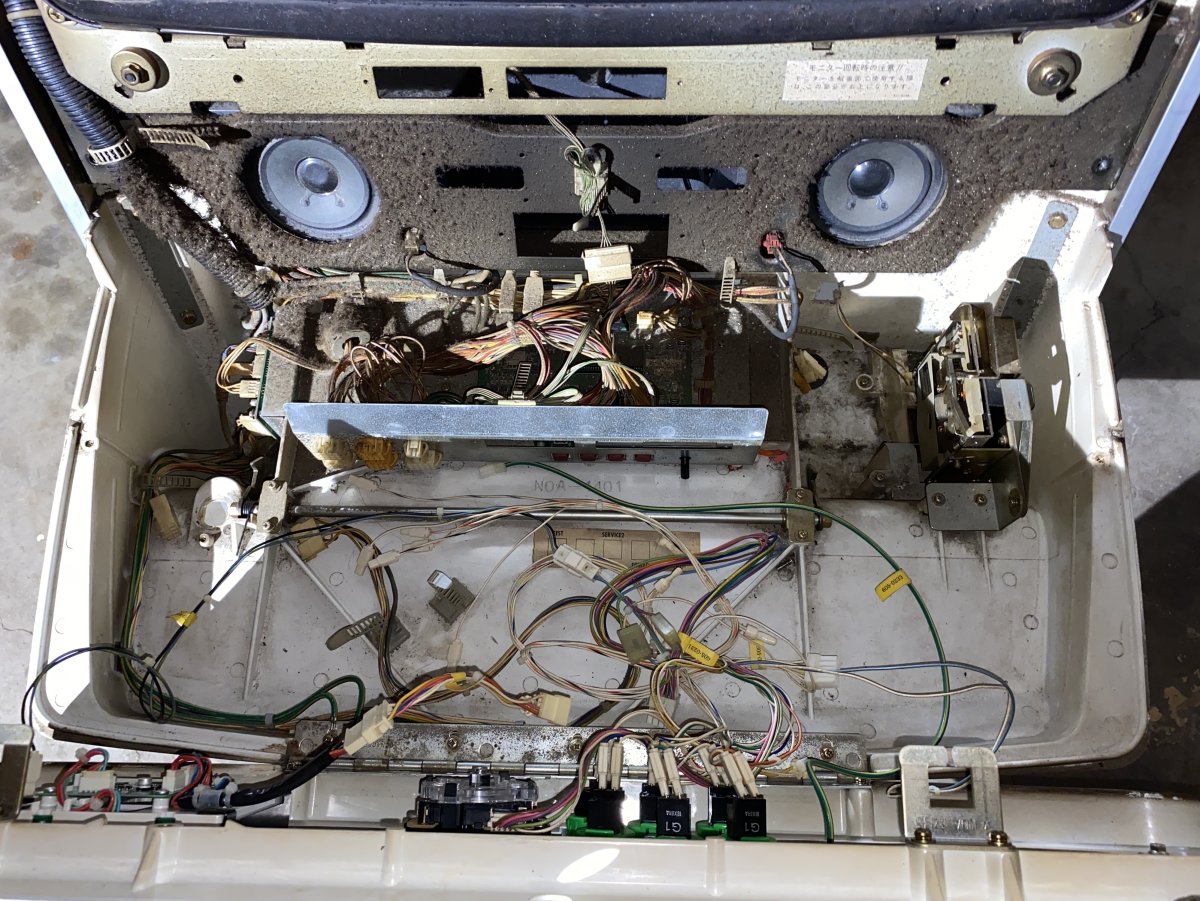

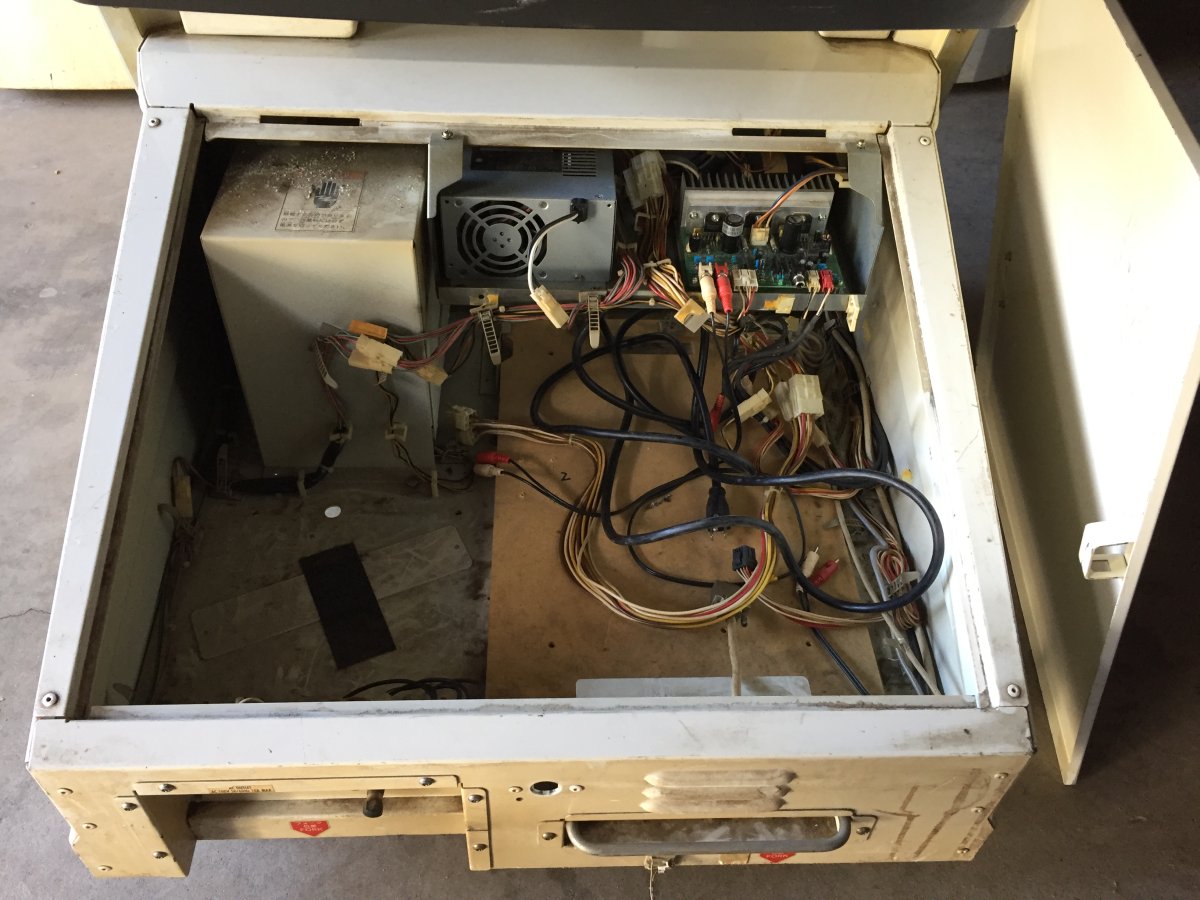

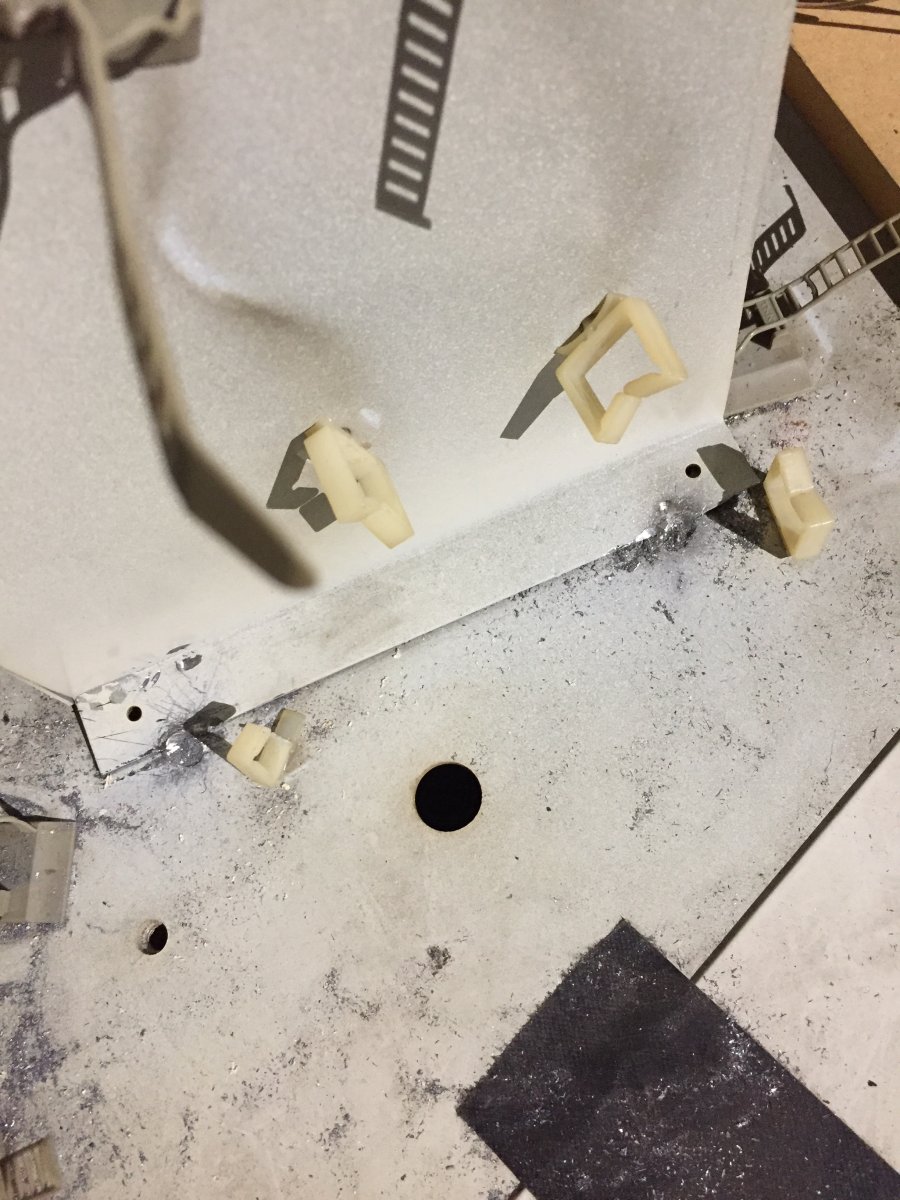

As usual everything was filthy dirty, the wiring a mess, missing fasteners, no locks, broken parts, damaged and yellowed paint, etc. Outside didn't look too horrible but the inside was nasty. Some disintegrated foam made the filth even worse. I'm still trying to determine where the foam originally was located. In the manual there's supposed to be some foam near the light fixture area but I'm not exactly sure where or what its purpose is.

The coin box was welded down in the back and I drilled through the welds so I could pull the box out for deep cleaning. There are screw holes already there so I only need to find some screws to fit and secure the box back down later.

Krud Kutter works well to remove most of the stains but doesn't restore the paint color completely. The paint is still various shades of greyish yellow white even after a thorough cleaning with undiluted Kutter.

It's been a year and a half since I received a trio of Cities from KC and I'm finally getting work done on the third and final City, the Net City. I have always liked the look of the Naomi/Net City series of cabinets so it was at the top of my list when cabinet shopping. Plus I wanted one cabinet with JVS support. The tri-sync monitor is cool too. I specifically requested an Old Net City instead of a New Net City only because I prefer the orange stylings. I had no idea that the New Net City has a superior monitor.

Here's what I got:

The guy making the delivery had a pickup with a small hydraulic lift cart that wasn't working. So we had to lift the cabinets out of the truck. The Astro and Blast went down okay. The Net has some extra weight and an awkward shape so it didn't come off the tailgate too smoothly. It took a hit to the back on the way down. Fortunately nothing looked damaged and the plastic monitor cover absorbed the impact.

I repeatedly requested and reminded KC to include a marquee holder and luckily he sent one. It wasn't attached to the cabinet when it arrived and I had to ask the delivery guy before he drove off to look for it under some stuff in the back of his truck and he found it. I had to be persistent to get that marquee holder and I'm glad to have it.

I disassembled and cleaned everything a full year ago and the parts have been all sitting in a pile since. Restoring the Astro and Blast Cities took a long time and I didn't want to deal with the Net until those were done. I did a quick test with a Dreamcast on the day the cabinet arrived just to make sure the monitor worked and that was it. I saw some convergence problems in the corners of the screen but otherwise the picture looked okay.

As usual everything was filthy dirty, the wiring a mess, missing fasteners, no locks, broken parts, damaged and yellowed paint, etc. Outside didn't look too horrible but the inside was nasty. Some disintegrated foam made the filth even worse. I'm still trying to determine where the foam originally was located. In the manual there's supposed to be some foam near the light fixture area but I'm not exactly sure where or what its purpose is.

The coin box was welded down in the back and I drilled through the welds so I could pull the box out for deep cleaning. There are screw holes already there so I only need to find some screws to fit and secure the box back down later.

Krud Kutter works well to remove most of the stains but doesn't restore the paint color completely. The paint is still various shades of greyish yellow white even after a thorough cleaning with undiluted Kutter.