Hi All,

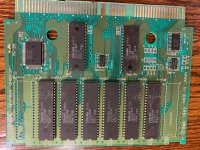

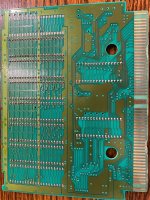

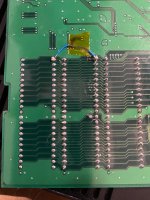

A buddy of mine gave me his Metal Slug MVS cart. He told me it was not working and giving a black screen or the test pattern. I noticed the contacts look like they have been damaged. Potentially from being inserted in correctly?

Anyway wanted to get eyes on it to see if it is worth working on.

Appreciate your feedback!

A buddy of mine gave me his Metal Slug MVS cart. He told me it was not working and giving a black screen or the test pattern. I noticed the contacts look like they have been damaged. Potentially from being inserted in correctly?

Anyway wanted to get eyes on it to see if it is worth working on.

Appreciate your feedback!