I recently picked up a Neo Geo MVS-4-25 v3 from a local collector looking to free up some space in his garage. I've always wanted a Neo Geo cabinet, and this has always been my favorite model. This cabinet and the sound of the Neo Geo splash screen during attract mode are core parts of the arcade experience in my mind.

This cabinet is rough. It was sold as a project machine, and it's definitely that. While I've done tons of arcade repairs and upgrades over the years, I've never done a full restore. I've been looking to take one on, and this cabinet perfectly fits the bill. I'm really bad at photographing and documenting my projects, so I'm starting this restoration thread in hopes that it will force me to do better.

The biggest issue with this cabinet is water damage. The back panels are crumbling and need to be replaced completely. The wood is swollen and falling apart all around the bottom of the cabinet. And it looks like someone was going for the world record of most holes drilled into a coin door panel.

The side panels are in okay shape except for water damage around the edges. The is most evident on the left panel.

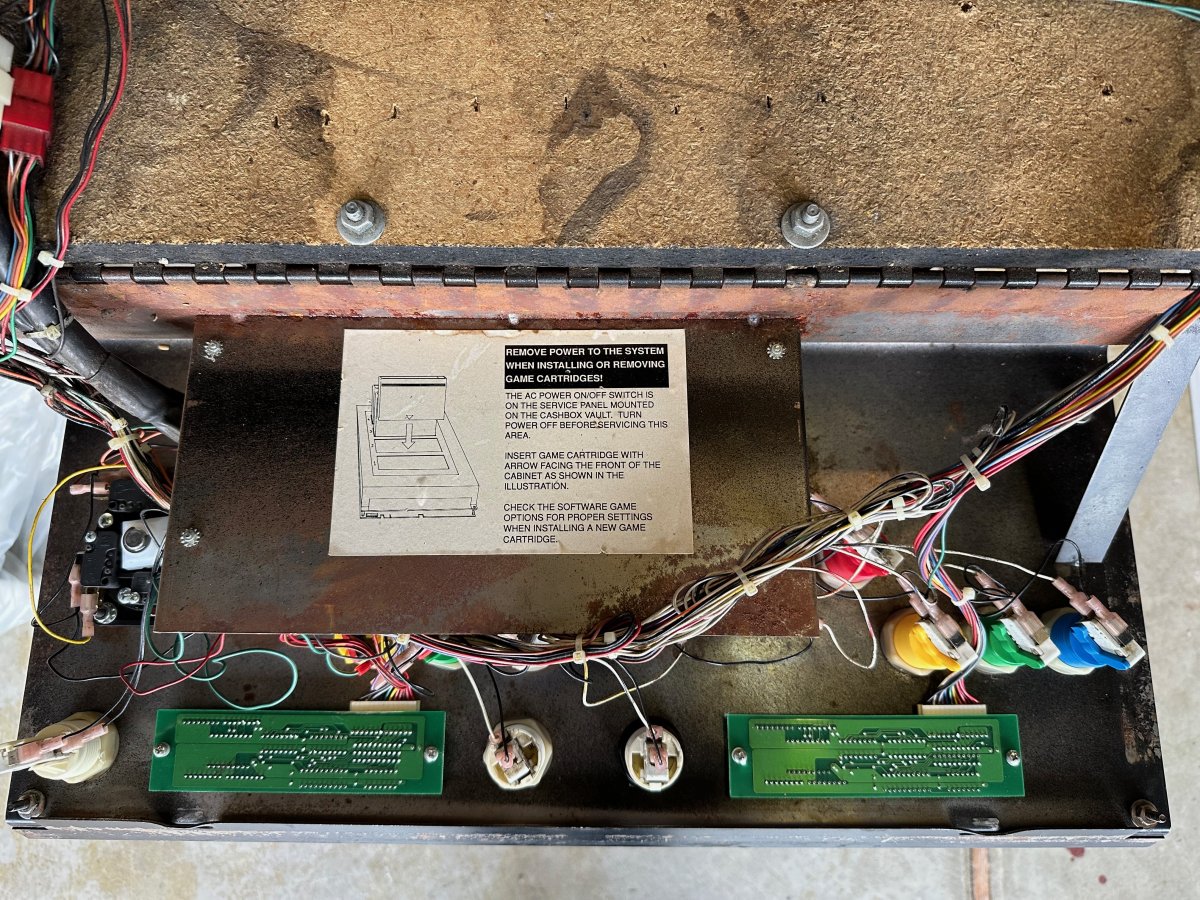

The control panel is in okay shape, but pretty beat up. Lots of rust on the inside. It has all the electronic components including the (not pictured) card reader + headphone board. Buttons are pretty crap, but the joysticks are new!

The coin door has been poorly touched up and show some rust. Needs extensive retouching or repainting.

The metal marquee cover looks pretty good! I think I can get away with just touching it up.

The inside is a bit more grim. The speakers are rotting, the mini marquee holder is yellowed, and the light panel isn't working.

This cabinet is rough. It was sold as a project machine, and it's definitely that. While I've done tons of arcade repairs and upgrades over the years, I've never done a full restore. I've been looking to take one on, and this cabinet perfectly fits the bill. I'm really bad at photographing and documenting my projects, so I'm starting this restoration thread in hopes that it will force me to do better.

The biggest issue with this cabinet is water damage. The back panels are crumbling and need to be replaced completely. The wood is swollen and falling apart all around the bottom of the cabinet. And it looks like someone was going for the world record of most holes drilled into a coin door panel.

The side panels are in okay shape except for water damage around the edges. The is most evident on the left panel.

The control panel is in okay shape, but pretty beat up. Lots of rust on the inside. It has all the electronic components including the (not pictured) card reader + headphone board. Buttons are pretty crap, but the joysticks are new!

The coin door has been poorly touched up and show some rust. Needs extensive retouching or repainting.

The metal marquee cover looks pretty good! I think I can get away with just touching it up.

The inside is a bit more grim. The speakers are rotting, the mini marquee holder is yellowed, and the light panel isn't working.

Last edited: