BladeZX

Champion

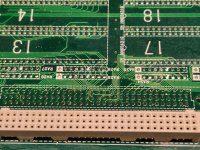

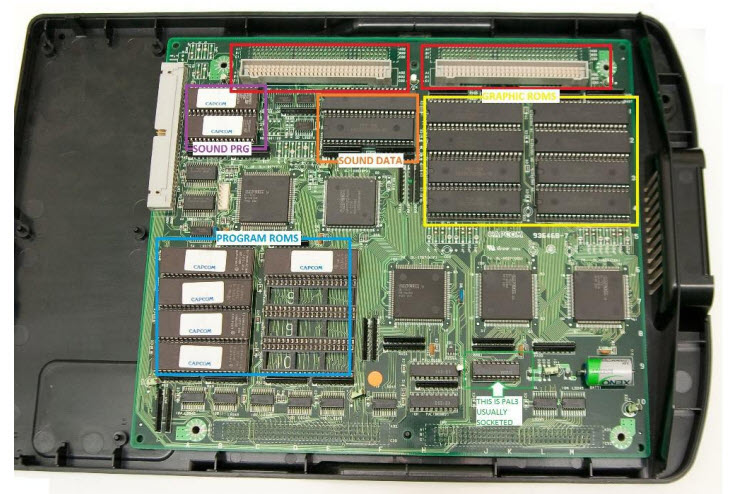

I will be getting my CPS2 multi today and quickly looking at the instructions and my B board it looks like I am missing the connectors on my board that are highlighted in RED in the instructions

See images below

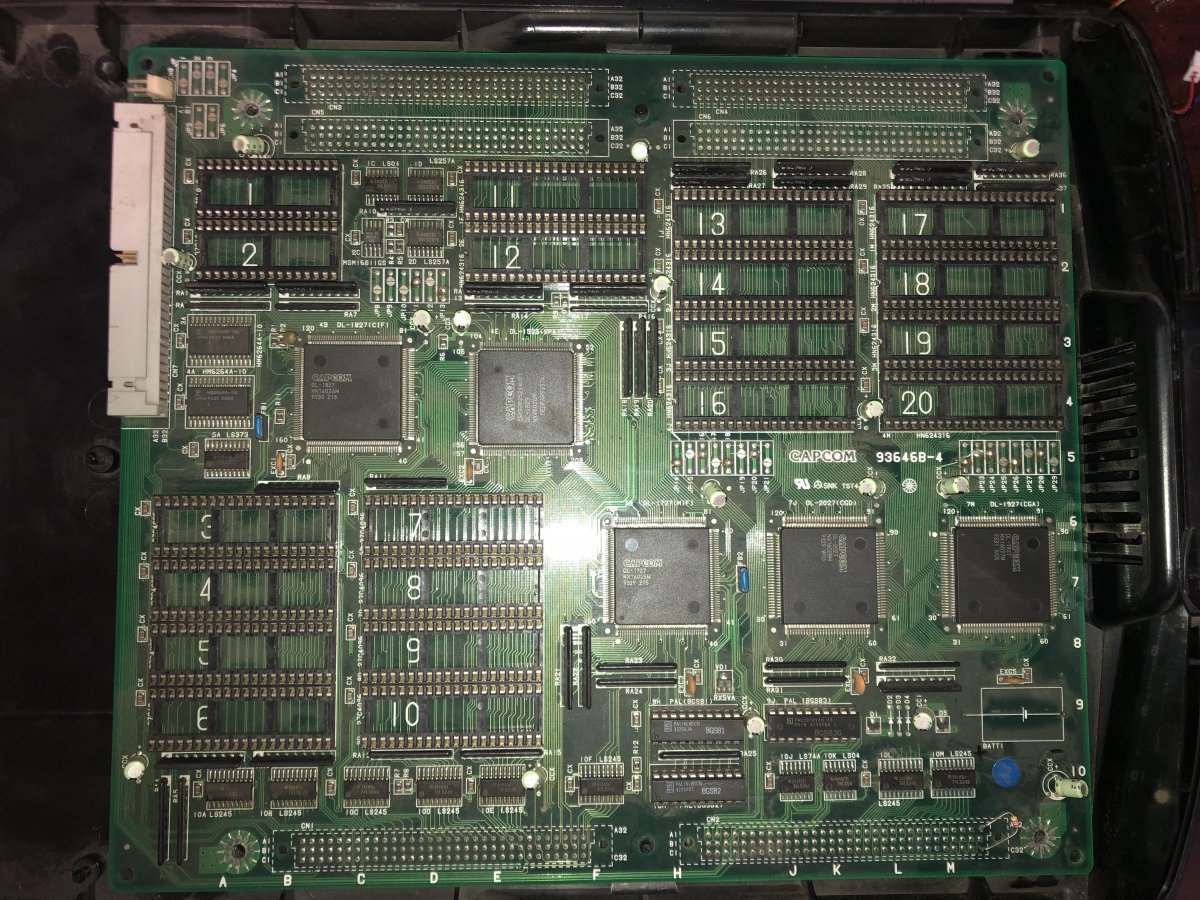

Here is my 93646B-4 board - I appear to be missing the connectors outlined in RED

It looks like the CPS2 multi main board plugs into them

@Darksoft @Mitsurugi-w

Am I completely out of luck here with my B board?

See images below

Here is my 93646B-4 board - I appear to be missing the connectors outlined in RED

It looks like the CPS2 multi main board plugs into them

@Darksoft @Mitsurugi-w

Am I completely out of luck here with my B board?