cpsystem3

Enthusiast

The monitor has been sold

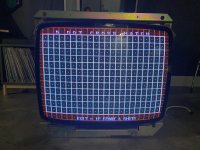

I’ve got a spare Nanao MS8-26 complete monitor in fully working condition for sale.

The good:

*The MS8-26 chassis has been deep cleaned, recapped, rebuilt and fully dialed in. It works perfectly fine and looks great.

*Zero burn-in that I can detect

*Comes with a 2-prong AC power harness and a Degauss push button harness

*Tube has been deep cleaned

*Yoke has been dialed in

The bad:

*The tube has several glass chips in the face. They are not too deep and barely noticeable when running. A free glass polishing kit is included. It consists of an orbital buffer, buffing pads and ceramic oxide to do a DIY buffing job. While I cannot guarantee the results, I do personally feel the chips can be buffed out based on other restorations I’ve seen.

Price: $250

Location: Medford, MA (just outside of Boston)

Pickup only

Thanks for looking!

I’ve got a spare Nanao MS8-26 complete monitor in fully working condition for sale.

The good:

*The MS8-26 chassis has been deep cleaned, recapped, rebuilt and fully dialed in. It works perfectly fine and looks great.

*Zero burn-in that I can detect

*Comes with a 2-prong AC power harness and a Degauss push button harness

*Tube has been deep cleaned

*Yoke has been dialed in

The bad:

*The tube has several glass chips in the face. They are not too deep and barely noticeable when running. A free glass polishing kit is included. It consists of an orbital buffer, buffing pads and ceramic oxide to do a DIY buffing job. While I cannot guarantee the results, I do personally feel the chips can be buffed out based on other restorations I’ve seen.

Price: $250

Location: Medford, MA (just outside of Boston)

Pickup only

Thanks for looking!

Attachments

-

IMG_7501.jpeg411.7 KB · Views: 103

IMG_7501.jpeg411.7 KB · Views: 103 -

IMG_3106.jpeg243.4 KB · Views: 97

IMG_3106.jpeg243.4 KB · Views: 97 -

IMG_3105.jpeg329.7 KB · Views: 97

IMG_3105.jpeg329.7 KB · Views: 97 -

IMG_3103.jpeg259.7 KB · Views: 95

IMG_3103.jpeg259.7 KB · Views: 95 -

IMG_7630.jpeg471.5 KB · Views: 102

IMG_7630.jpeg471.5 KB · Views: 102 -

IMG_7581.jpeg486.1 KB · Views: 85

IMG_7581.jpeg486.1 KB · Views: 85 -

IMG_7555.jpeg421.2 KB · Views: 85

IMG_7555.jpeg421.2 KB · Views: 85 -

IMG_7522.jpeg425 KB · Views: 77

IMG_7522.jpeg425 KB · Views: 77 -

IMG_7516.jpeg356.2 KB · Views: 93

IMG_7516.jpeg356.2 KB · Views: 93

Last edited: