You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Thread starter twistedsymphony

- Start date

I don't own any CPS 2 hardware so unless there's already a model for them I'd need something in my hands to work with/test fit.T, can you do CPS2 Buttons? I have been looking to get these made for a while, but I suck at the 3d model cad file stuff.

It's available to download. The quality of the buttons varies greatly depending on the printer though. When I printed mine I had to file it down in parts quite a bit to get it to fit.

Hmmm...we are gonna have to take care of that, I have spare MB/Cart I can send yaI don't own any CPS 2 hardware so unless there's already a model for them I'd need something in my hands to work with/test fit.

Mitsu, do you have any links? I have been unable to find one to download the 3d model.It's available to download.

I've been unable to find any files for this (though I haven't looked that hard).

If anyone has a reasonably priced Mars Matrix board for sale that's one CPS2 game I'd been considering buying. CPS2 in general has been a hard sell for me since it's emulated very well.

----

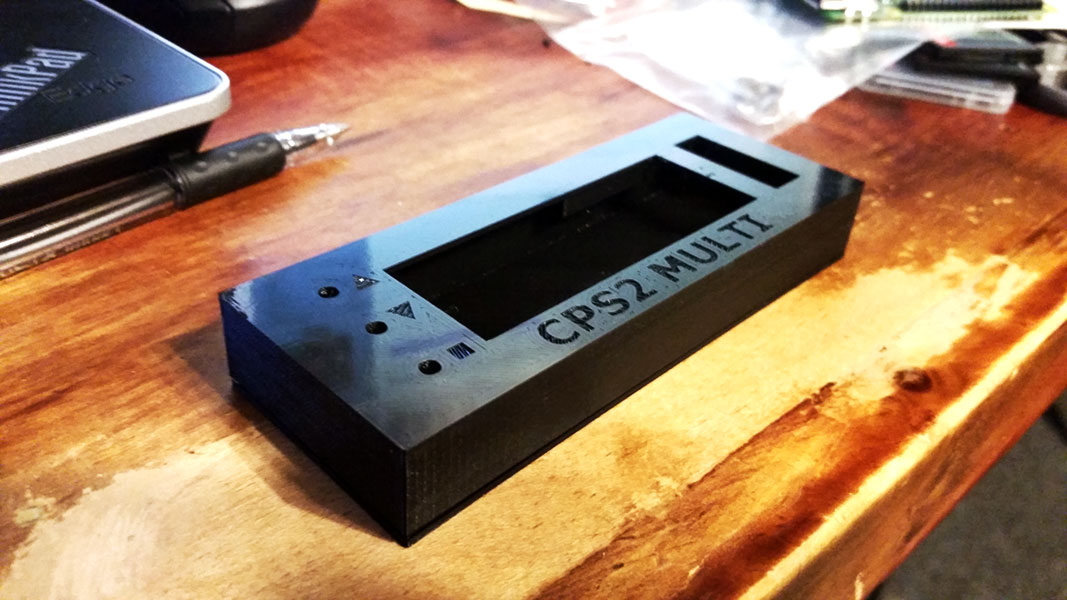

I did do a test print of the CPS2 LCD holder this morning... it's a very small part so fairly quick and cheap to print but I'm still concerned about the edge breaks. all the corners are sharp and have a slight lip on them so it may cause problems for the buttons and screws.

If anyone has a reasonably priced Mars Matrix board for sale that's one CPS2 game I'd been considering buying. CPS2 in general has been a hard sell for me since it's emulated very well.

----

I did do a test print of the CPS2 LCD holder this morning... it's a very small part so fairly quick and cheap to print but I'm still concerned about the edge breaks. all the corners are sharp and have a slight lip on them so it may cause problems for the buttons and screws.

Dreamstate

Enthusiast

So, are you making it with PVC? Can you "sand" down edges? Just thinking through it.

It's PLA material, and yeah you can sand down the material but really you shouldn't have to.

I feel if I'm going to sell something it should be something that you can just use without having to "finish" it.

I feel if I'm going to sell something it should be something that you can just use without having to "finish" it.

Whenever I print the CPS2 lcd case I always need to widen the holes a bit. Never problems with the screw holes.

Here is the CPS2 button thread:

CPS2 menu and volume

Here is the CPS2 button thread:

CPS2 menu and volume

Thanks for the link, that looks like a pretty tricky part to print, especially since the flex part should be printed along the x/y axis to prevent cracking from layer separation. That seems like one part that might be better suited to a redesign as opposed to a direct replica.

On your CPS2 multi cases you say the screw holes don't need widening but do the screws sit flush in the bottom or do they stick out... they SHOULD sit flush based on the design, but I don't think they have the right clearances.

On your CPS2 multi cases you say the screw holes don't need widening but do the screws sit flush in the bottom or do they stick out... they SHOULD sit flush based on the design, but I don't think they have the right clearances.

Dreamstate

Enthusiast

I don't know if it is an option, but I thought I was reading that PVC worked better since it is not so fragile. If that is an option, you may want to try it. Obviously, that does not change the tolerance adjustments you were talking about. EDIT: I am still on the case conversation and not the button noe to be clear.

AFAIK there is only one company that makes a PVC filament and it's essentially experimental at this point. from what I've read it doesn't sound all that great in terms of strength, it's biggest selling point is that it's easily recyclable.

what's your beef with PLA?

what's your beef with PLA?

Dreamstate

Enthusiast

Just that it is brittle. I thought PVC was much more main stream, but I have not looked into it that much myself. I just was judging from the 3DBox and some other site where printers show their options. Seemed like PVC was better, but is not a well educated opinion

PLA isn't brittle. We've used it with great success for tooling fixtures at my work where we manufacture aircraft parts.

When compared to ABS it's not quite as strong. mostly because ABS has a bit of a rubbery property to it, but most of my PLA prints you could throw at the wall hard and they'd come out unscathed.

I use PLA because it's more than strong enough for these kinds of things AND it has a higher quality finish and is more dimensionally accurate than any other material. Since most of these things serve a decorative purpose as much as a protective purpse choosing a material that will look nice and fit well is ever much as important as the protective aspects.

There are a handfull of parts where I make them in ABS and that are things such as the Sega Saturn battery door. since the part needs to bend under normal use ABS is more suited for that. Similarly I'll likely make the CPS2 buttons out of ABS for the same reason. ABS shrinks when cooling, this is extremely difficult to control for so parts have more difficulty fitting properly, but it's worth this annoyance in some applications for the bending properties. ABS is also better for higher temps so for instance I used it when designing headlight brackets for my car since it's going to be in a very hot environment.

For cartridges the PLA material is actually very well suited. It has some of the best wear resistance properties of any of the filaments available, it's far less likely to wear down over time compared to other materials so for use in a device that sees friction against other surfaces regularly it's arguably the best material for the job.

90% FMD 3D prints use those two materials, there are some new materials that blend the two to give you basically something that's half way between the two (a little stronger and higher temp than PLA but a little better dimensionally than ABS) but I find that's typically more suited for people who just want to buy one material that works "pretty good" for everything rather than picking a particular material thats suited for the particular part.

Nylon is another option, it wears better than PLA, is stronger than ABS and and handle higher temps than ABS, however it's nearly impossible to print with, dimensions are extremely difficult to nail down since it has a high propensity to warp and the finish on the final part usually looks like garbage. Not to mention the color options are mostly just "natural" which is like a yellowly, slightly translucent white. About the only application it's worth using Nylon for is if you're making something like custom gears that will see lots of constant wear, high stresses and heat.

When compared to ABS it's not quite as strong. mostly because ABS has a bit of a rubbery property to it, but most of my PLA prints you could throw at the wall hard and they'd come out unscathed.

I use PLA because it's more than strong enough for these kinds of things AND it has a higher quality finish and is more dimensionally accurate than any other material. Since most of these things serve a decorative purpose as much as a protective purpse choosing a material that will look nice and fit well is ever much as important as the protective aspects.

There are a handfull of parts where I make them in ABS and that are things such as the Sega Saturn battery door. since the part needs to bend under normal use ABS is more suited for that. Similarly I'll likely make the CPS2 buttons out of ABS for the same reason. ABS shrinks when cooling, this is extremely difficult to control for so parts have more difficulty fitting properly, but it's worth this annoyance in some applications for the bending properties. ABS is also better for higher temps so for instance I used it when designing headlight brackets for my car since it's going to be in a very hot environment.

For cartridges the PLA material is actually very well suited. It has some of the best wear resistance properties of any of the filaments available, it's far less likely to wear down over time compared to other materials so for use in a device that sees friction against other surfaces regularly it's arguably the best material for the job.

90% FMD 3D prints use those two materials, there are some new materials that blend the two to give you basically something that's half way between the two (a little stronger and higher temp than PLA but a little better dimensionally than ABS) but I find that's typically more suited for people who just want to buy one material that works "pretty good" for everything rather than picking a particular material thats suited for the particular part.

Nylon is another option, it wears better than PLA, is stronger than ABS and and handle higher temps than ABS, however it's nearly impossible to print with, dimensions are extremely difficult to nail down since it has a high propensity to warp and the finish on the final part usually looks like garbage. Not to mention the color options are mostly just "natural" which is like a yellowly, slightly translucent white. About the only application it's worth using Nylon for is if you're making something like custom gears that will see lots of constant wear, high stresses and heat.

still need some help?is there someone in the New-England area with a CPS2 multi that can do some test fitting for me?

Dreamstate

Enthusiast

Yeah, so I was thinking ABS when I kept saying PVC. Thanks for the explaination of everything. At some point, I am going to get a printer and mess with this stuff.

I did, I've been a flake all month due to work and coming home late. January's my dogshit month due to Wall Street deadlines. I'd also like to say thanks again for raffling that off!Did you get the LCD case I sent you?I'd buy one of the ST-V Multi Cart housings

I had some setbacks as my printer broke last Sunday and then I came down with a nasty cold. so most of this week I've done almost nothing on this trying to get some rest.

The last two days I spent most of my time finishing up the store, running a few test orders to make sure everything was working right So I think it's ready!

[align=center]

https://bit-district.com[/align]

Please check out the store, order up whatever it is you'd like to buy, and let me know if you run into any problems.

I'd like to keep this Arcade-Projects.com only for the first week or so just to make sure you guys get first crack at my inventory.

The last two days I spent most of my time finishing up the store, running a few test orders to make sure everything was working right So I think it's ready!

[align=center]

https://bit-district.com[/align]

Please check out the store, order up whatever it is you'd like to buy, and let me know if you run into any problems.

I'd like to keep this Arcade-Projects.com only for the first week or so just to make sure you guys get first crack at my inventory.

Dreamstate

Enthusiast

Sorry you have been feeling bad! I just ordered a few things and had no issue. Store looks nice.