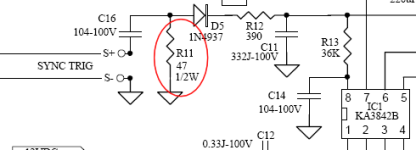

I turned off my AWSD (with a wei-ya 3129D, Samsung Tube) the other night after playing for about an hour, went to turn it on the next morning and had HV shutdown with the relays clicking on and off every second or so, and the flyback trying to start up.

I pulled the chassis and looked it over, but couldn't find any problems on the chassis itself. Caps are brand new and every joint has been retouched.

The HOT and a handful of other random selection of transistors and diodes all tested ok out of circuit.

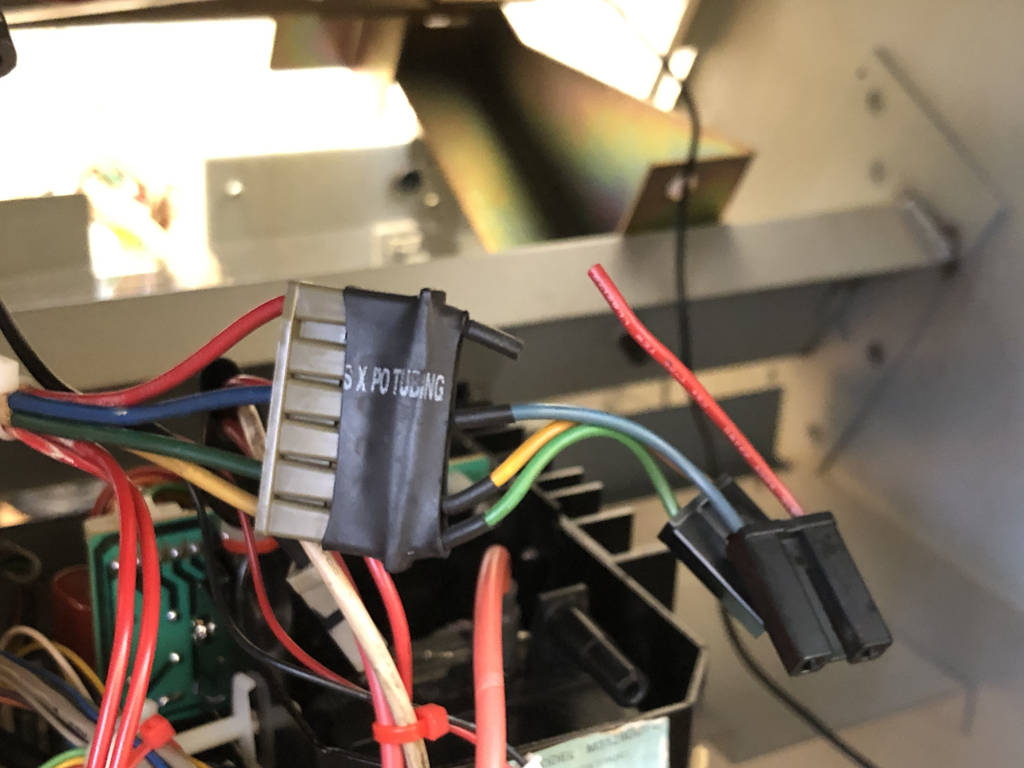

When I was putting it back in the cab, I found the horizontal yoke wire broken at the "adapter".

I'm thinking this killed the yoke somehow.

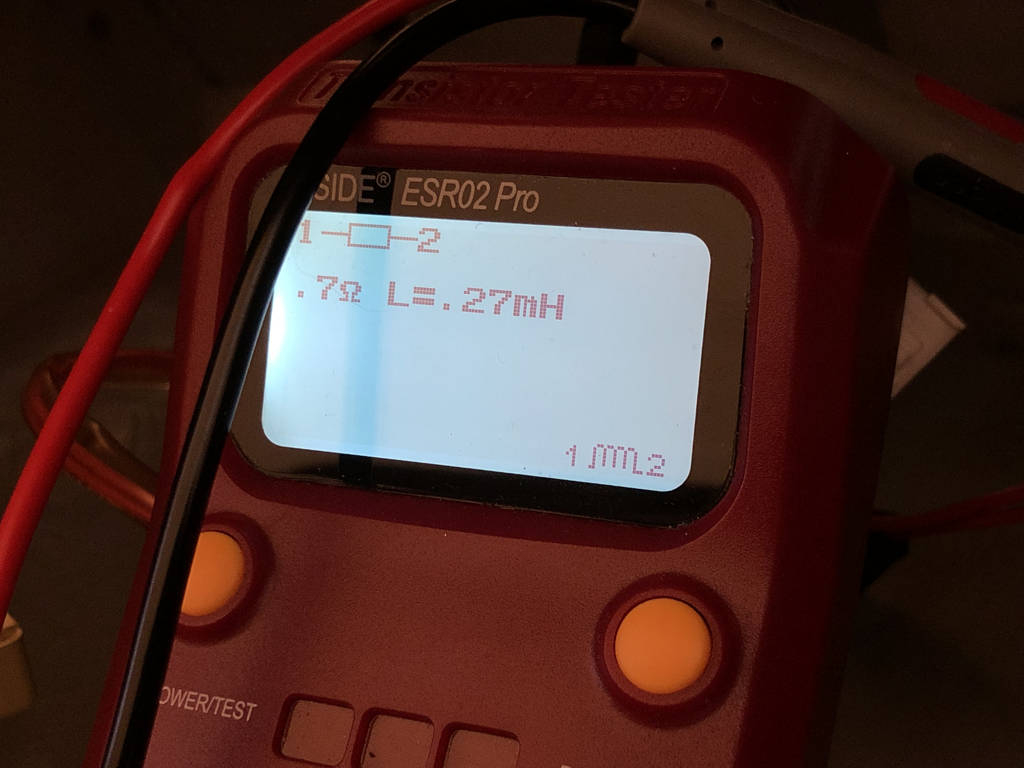

Measuring the yoke's horizontal Inductance shows it close to spec (0.27mH) but I don't think an almost dead short of 0.7 ohms is ok.

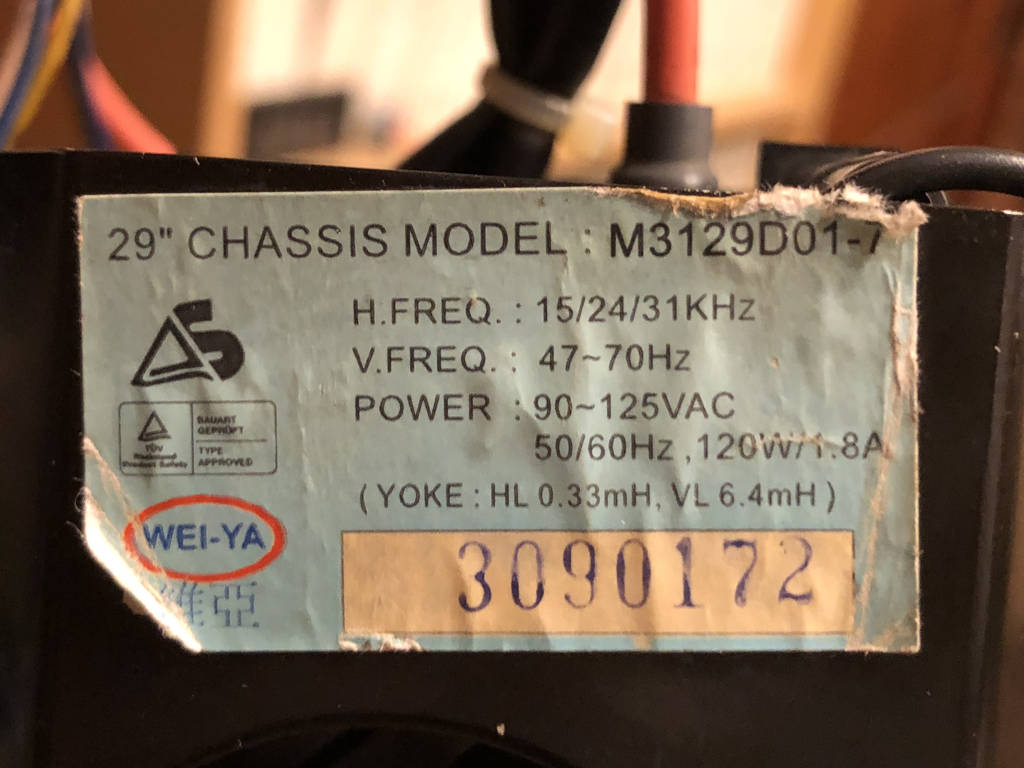

The chassis label unfortunately makes no mention about resistance.

Any ideas, other advice, or leads on a spare? Deflection yoke model is Samsung DIF-2912DA

I pulled the chassis and looked it over, but couldn't find any problems on the chassis itself. Caps are brand new and every joint has been retouched.

The HOT and a handful of other random selection of transistors and diodes all tested ok out of circuit.

When I was putting it back in the cab, I found the horizontal yoke wire broken at the "adapter".

I'm thinking this killed the yoke somehow.

Measuring the yoke's horizontal Inductance shows it close to spec (0.27mH) but I don't think an almost dead short of 0.7 ohms is ok.

The chassis label unfortunately makes no mention about resistance.

Any ideas, other advice, or leads on a spare? Deflection yoke model is Samsung DIF-2912DA

Last edited: