kebrank

Enthusiast

- Joined

- Sep 1, 2015

- Messages

- 162

- Reaction score

- 102

Great design and price, very cool. I have a question and a couple of suggestions.

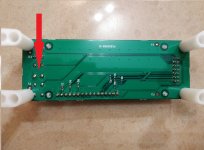

About the LCD, I see a couple of cutouts and the ribbon that connects to the LCD going through them. Is there a reason for this?

Cutouts are cool but one of the points of having the multi enclosed is to avoid the acumulation of dust on the PCB.

I think it would be a good idea to have a + - and a T, for the Volume up, down and Test buttons. Same thing from the LCD panel buttons.

About the fan, given the original one is 60 mm if i’m not making a mistake, the 80 mm Noctua should be perfect for the case.

Thanks,

\o/.k.

About the LCD, I see a couple of cutouts and the ribbon that connects to the LCD going through them. Is there a reason for this?

Cutouts are cool but one of the points of having the multi enclosed is to avoid the acumulation of dust on the PCB.

I think it would be a good idea to have a + - and a T, for the Volume up, down and Test buttons. Same thing from the LCD panel buttons.

About the fan, given the original one is 60 mm if i’m not making a mistake, the 80 mm Noctua should be perfect for the case.

Thanks,

\o/.k.