The new speakers and new tweeters sound great and I'm impressed with how full the sound is with such tiny woofers. The Blast City's ported enclosure really helps to pull out some lower frequencies. But once again there is a little problem. A problem for me anyway. With both the game PCB and Blast volume turned to max, the sound level is okay, but not loud. I want it LOUD. So I added an amplifier:

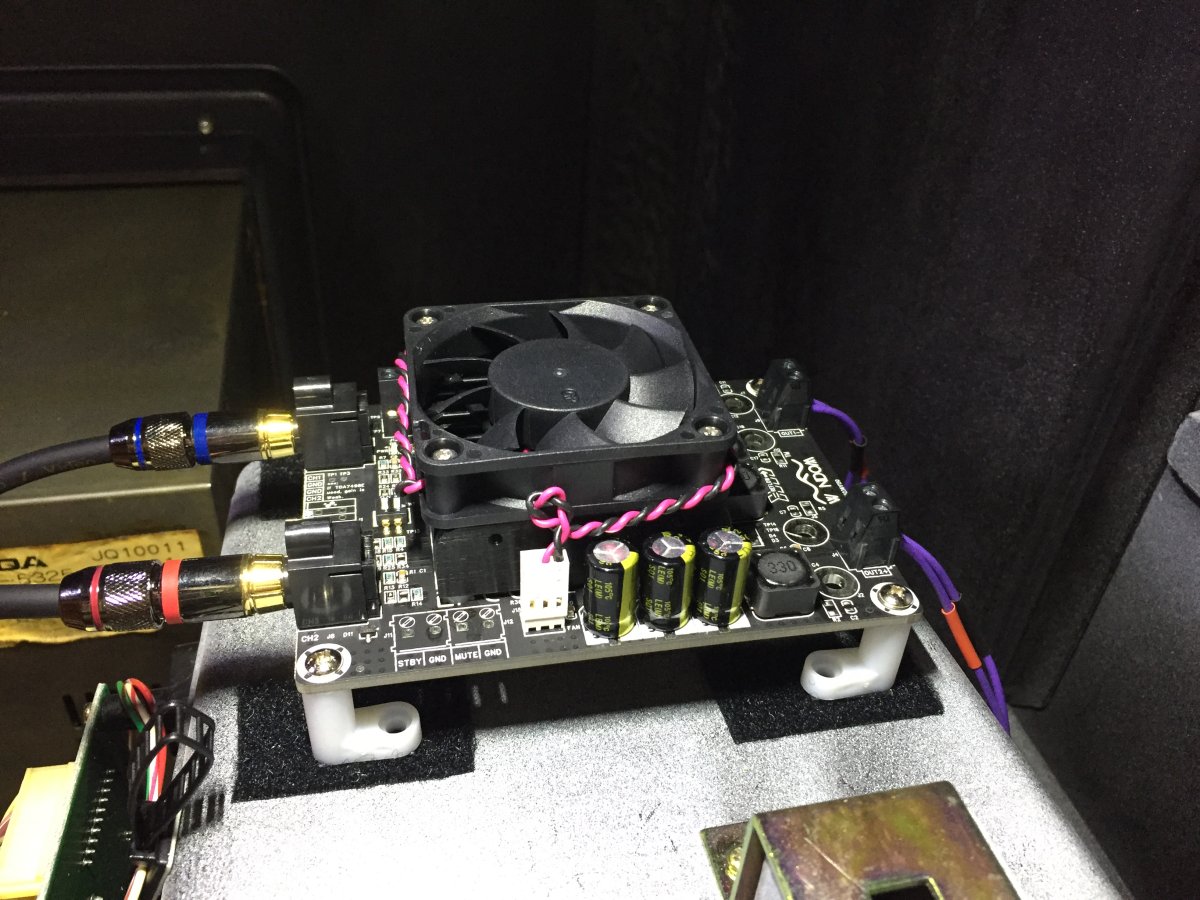

This is the WONDOM AA-AB32189 2x100W TDA7498 Class-D Amplifier from Parts Express. And with 100 watts at 6 ohms it gives me exactly what I wanted. I'm only getting about a third of that power due to my 8 ohm speakers being connected in series but it's more than enough (the Peerless woofers are only rated for 10 watts each anyway). I have the amp set to medium level and with my volume knob at the front of the cabinet turned up less than half way it's very loud, and very clear. My Blast speakers were wrecked when I got the cabinet so I don't know how they sounded and can't make a comparison. But I can say that these new speakers and amp sound much better than the Logitechs in my Astro City. I plan to add one of these amplifiers to the Astro for improved sound and stereo. I expect it still won't sound as good since the speakers aren't in a proper enclosure like the Blast has.

I pulled the original Blast amplifier out, bought some JST connector headers, and utilized the original connections for the new amp and a line output converter.

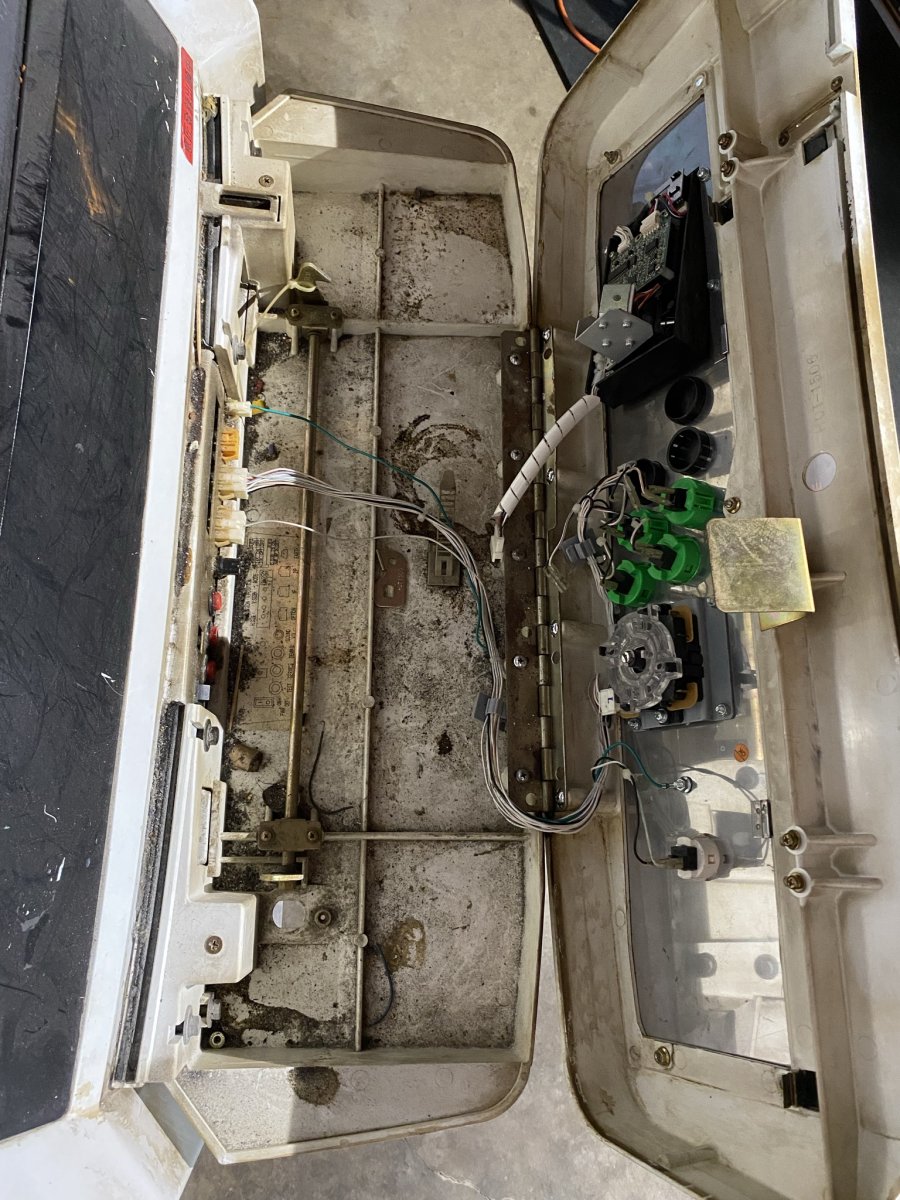

Original amplifier with JST connectors CN1-CN4:

And here is CN2, CN3, and CN4 routing the JAMMA audio signal through a line converter, to the volume control under the control panel, to the new amplifier, then to the speakers:

The converter and JST connectors are mounted with adhesive Velcro in the spot where the original amp was. I routed RCA connections for the amplifier input and speaker inputs (amplifier output) through the opening of the power supply case where the 32 pin connector is:

No wires were cut and everything can be unplugged and returned to stock condition if I want (not likely).

For power I utilized CN13 on the terminal board. I cut the end off of an AC power splitter and added an AMP UP 3 pin connector. I'm using a power splitter so that I have an additional AC power plug in case I ever add something else to the cabinet in the future that needs 120V AC. The ground wire is connected to the screw in front of the power supply where the other ground wires are connected:

I placed the new amplifier power supply behind the coin box and used adhesive Velcro to secure it in place.

And since I was buying these connectors I bought one to bypass the door switch: