You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Thread starter FrancoB

- Start date

For Sale

Great stuff man! Looks fab!  Thanks for your feedback and help so far!

Thanks for your feedback and help so far!

I've not finished the main assembly video yet as I've been working on a couple of improvements and I wanted to get them done first so they can be included. One good thing is everyone has been able to assemble the kits just using the product video which shows they're pretty easy to fit.

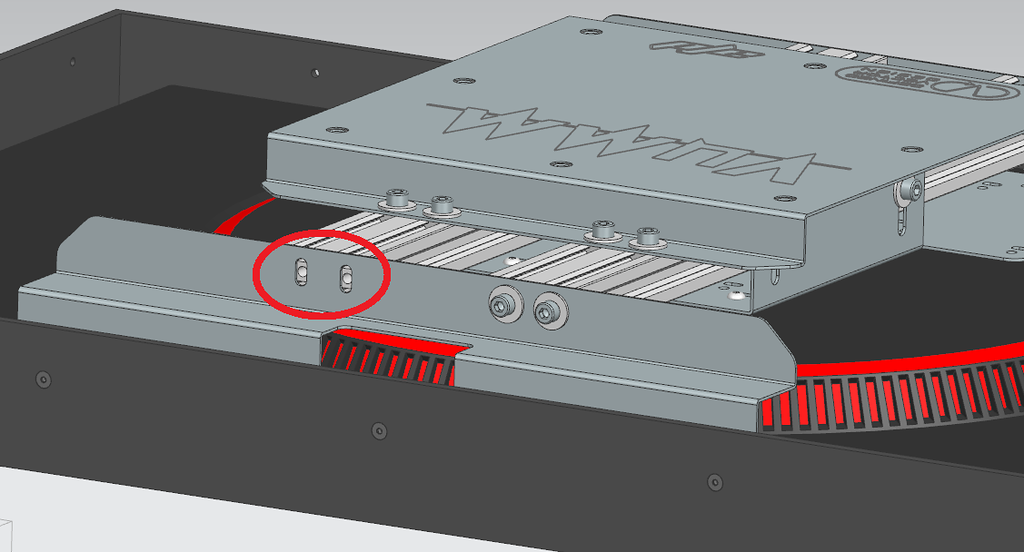

The first thing I'm thinking of doing is to elongate/slot the holes that attach the 2040 section to the end brackets:

All of the fabricated parts are precision pressed/bent and I've made a number of gauges to check that the parts are to spec, this is especially important due to tolerance stack up. All of the kits tested so far bar one have ended up with the monitor being near perfectly flush with the speaker assemblies on the front of the cab. For some reason, the monitor on one of the cabs that was tested on ended up being a couple of mm too short. I know it's not a difference/error in the kits due to the gauges/checking. The only thing I can't control is the accuracy of the cabs/original monitor assemblies and anything that has happened to the cabs since.

Slotting the holes as above would give +/-3mm of adjustment. If the mount is assembled with the 2040 section level with the top of the end brackets then this would be the '0' position. I would recommend assembling like that for a start and then adjusting from there after test fitting but only if required.

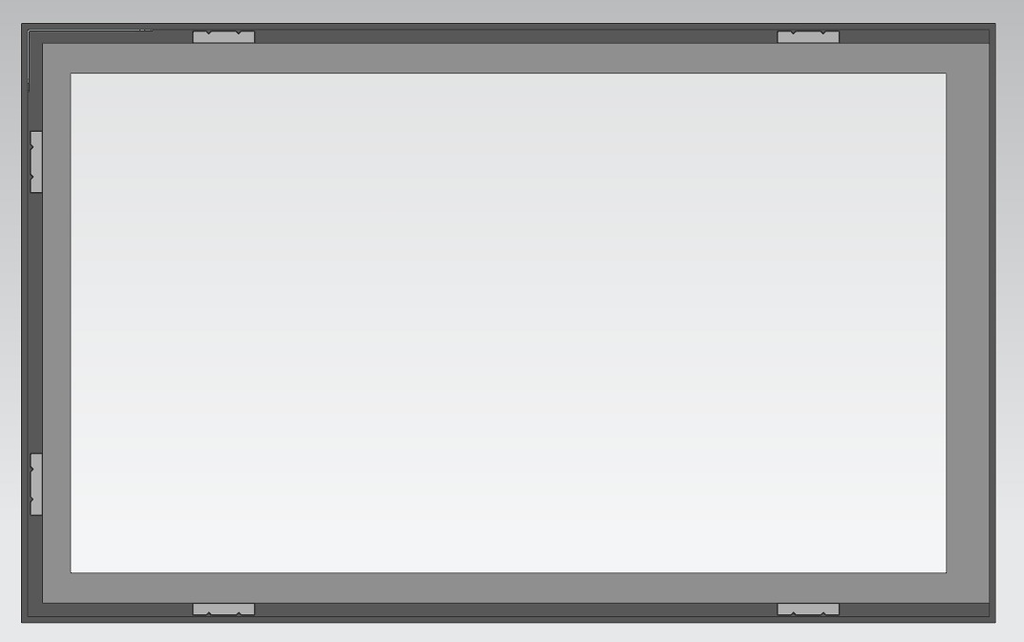

One other thing I wanted to address is the issue of the glass floating around in side the frame on Vewlix C, F and Ls. The glass is bonded to the front of the OEM LCD which holds it in place. The glass is removed from the OEM LCD and placed back into the frame prior to fitting the new display. The glass is approx 22mm shorter and 12mm narrower than the frame it sits in which means the glass can move around radially which isn't ideal. This isnt an issue for the Dia Blues etc as the glass is clamped in place as part of the frame assembly.

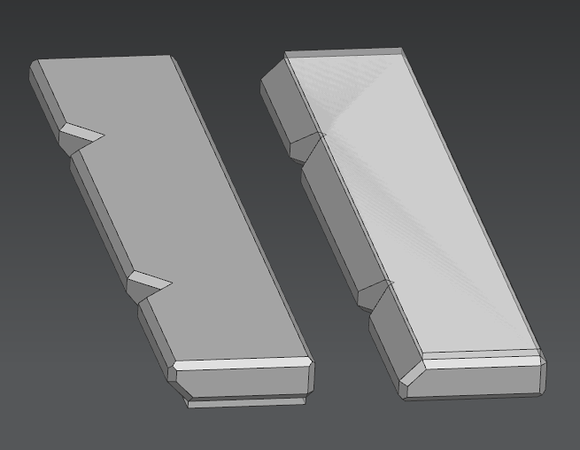

I'm thinking about making some ~10mm self adhesive shims/packers to take up the slack between the glass and the frame:

This should stop any radial movement.

I've got some printed and I'm going to send them out for testing. All being well I'll include them as part of the kit.

Otherwise, everything is looking good so far. I'm just waiting on some general feedback from one other person before I get batch two into production, speaking of which there are currently 3 frames/spaces left on batch 2.

Thanks for your feedback and help so far!

Thanks for your feedback and help so far!I've not finished the main assembly video yet as I've been working on a couple of improvements and I wanted to get them done first so they can be included. One good thing is everyone has been able to assemble the kits just using the product video which shows they're pretty easy to fit.

The first thing I'm thinking of doing is to elongate/slot the holes that attach the 2040 section to the end brackets:

All of the fabricated parts are precision pressed/bent and I've made a number of gauges to check that the parts are to spec, this is especially important due to tolerance stack up. All of the kits tested so far bar one have ended up with the monitor being near perfectly flush with the speaker assemblies on the front of the cab. For some reason, the monitor on one of the cabs that was tested on ended up being a couple of mm too short. I know it's not a difference/error in the kits due to the gauges/checking. The only thing I can't control is the accuracy of the cabs/original monitor assemblies and anything that has happened to the cabs since.

Slotting the holes as above would give +/-3mm of adjustment. If the mount is assembled with the 2040 section level with the top of the end brackets then this would be the '0' position. I would recommend assembling like that for a start and then adjusting from there after test fitting but only if required.

One other thing I wanted to address is the issue of the glass floating around in side the frame on Vewlix C, F and Ls. The glass is bonded to the front of the OEM LCD which holds it in place. The glass is removed from the OEM LCD and placed back into the frame prior to fitting the new display. The glass is approx 22mm shorter and 12mm narrower than the frame it sits in which means the glass can move around radially which isn't ideal. This isnt an issue for the Dia Blues etc as the glass is clamped in place as part of the frame assembly.

I'm thinking about making some ~10mm self adhesive shims/packers to take up the slack between the glass and the frame:

This should stop any radial movement.

I've got some printed and I'm going to send them out for testing. All being well I'll include them as part of the kit.

Otherwise, everything is looking good so far. I'm just waiting on some general feedback from one other person before I get batch two into production, speaking of which there are currently 3 frames/spaces left on batch 2.

Cheers guys! I'm excited to get these out to you too. Don't worry @marwien , everyone who has paid an invoice is well and truly in batch 2.

Update:

Batch 2 is full. I've left the order form open to gather any interest for a potential batch 3. I won't be sending any invoices out until both batch 2 is shipped and there is enough interest for a batch 3.

Feedback from all of the batch 1 kits has been good so I've gone ahead and placed the fabrication order (with the revised elongated holes) for batch 2. That looks like it should be complete towards the end of next week.

I've also ordered the rest of the hardware which has almost all arrived and I already have all packaging materials. Whilst waiting for the fabricated parts I'm going to put all of the hardware sets together and cut/prepare all of the packing materials (which takes an age) so that everything is ready to go when the fabbed parts land.

I made a few sets of the 'glass shims' shown above to a few people for testing. They were based off dimensions from one persons cab so I want to check them on a few cabs in case the sizes need tweaking so they'll fit all cabs that need them. Once I have feedback from those I can get them made in the mean time as well.

Update:

Batch 2 is full. I've left the order form open to gather any interest for a potential batch 3. I won't be sending any invoices out until both batch 2 is shipped and there is enough interest for a batch 3.

Feedback from all of the batch 1 kits has been good so I've gone ahead and placed the fabrication order (with the revised elongated holes) for batch 2. That looks like it should be complete towards the end of next week.

I've also ordered the rest of the hardware which has almost all arrived and I already have all packaging materials. Whilst waiting for the fabricated parts I'm going to put all of the hardware sets together and cut/prepare all of the packing materials (which takes an age) so that everything is ready to go when the fabbed parts land.

I made a few sets of the 'glass shims' shown above to a few people for testing. They were based off dimensions from one persons cab so I want to check them on a few cabs in case the sizes need tweaking so they'll fit all cabs that need them. Once I have feedback from those I can get them made in the mean time as well.

Filled out the form. Hoping for a batch 3!

Thanks man! Batch 3 is about 25% full. I'll start to send out invoices once it's closer to 75%.

I assume by Diamond Blue support the Diamond Black / Orange is also supported?

From what I've read recently the Blue uses a different monitor (P32L050 - 728p) to the Orange and Black (1080P).

From what I've seen I think the Orange/Black should also be supported. I would just need to get a few dimensions from an Orange & Black monitors to confirm. If you're interested in one and are willing to check a couple of dimensions then send me a PM.

UPDATE:

I got a lot of the packaging prepped over the last week or so and I've got the hardware buts/bolts kits put together as well as the 2040 wrapped.

Most of the fabbed parts arrived today and the rest are due on Wednesday and I'm starting to package these up tonight.

Glass shims:

The original plan was to print 6 glass packers and push the glass up to one side as per the post above. I did this because the side shims only need to be a few mm wide and they're not really wide enough to get a decent amount of double sided tape on. Pushing the glass to one side allowed me to use a shim double the width. One friend tested these for me though and he found he has some marks on his glass that were only hidden when the glass was central.

With that in mind I've changed the glass packers to be L shaped which should still allow them to be adhered in position but the shorter legs should now hold the glass centrally:

I've sent a set out of those out for testing and I'm waiting on feedback from those.

All being well I'm hoping to get most things wrapped and a few of the glass packers sets made and start shipping towards the end of this week with the rest to follow.

Thanks for your patience.

I'm very happy to report that after a lot of late nights batch 2 is fully completed, packed, shipped and tracking numbers have been sent to everyone

As mentioned in the tracking details, whilst parcels are in transit I’m going to create further video(s) / instructions to assist with installation etc.

I received feedback on the L shaped glass packers above and I've included a set with all orders.

If anyone has any questions in the meantime then just let me know.

A few more people have expressed interest in a potential batch 3 and that's looking to be around 40% full at the moment.

As mentioned in the tracking details, whilst parcels are in transit I’m going to create further video(s) / instructions to assist with installation etc.

I received feedback on the L shaped glass packers above and I've included a set with all orders.

If anyone has any questions in the meantime then just let me know.

A few more people have expressed interest in a potential batch 3 and that's looking to be around 40% full at the moment.

wigsplitta

Professional

Yesterday I received the awesome mount kit with a side dish of the smart coin rejector switch.

Many thanks to @FrancoB for sharing his great projects.

The mount kit was really easy to use.

The most complicated thing was to decide which frame to use.

My Vewlix C seems to be in between Taito revisions. It got the old style F/C four part bezel/frame (mounted to the back of the monitor!) and a new style one part frame but without a groove for the glass.

I picked the one piece frame despite the other having the Japanese epilepsy warning sticker

Fitting a new monitor with the VUMM was really easy. The short product video gives a good guide on how to use it.

I got only one thing I would change:

the glass packers should have more height (for the loose glass frames).

When I put the monitor upright for testing, the monitor did not have enough pressure to keep the glass fully down and the glass slipped over a packer.

In summary:

I this mounting solution. It's a must-have for Vewlix owners

this mounting solution. It's a must-have for Vewlix owners

Many thanks to @FrancoB for sharing his great projects.

The mount kit was really easy to use.

The most complicated thing was to decide which frame to use.

My Vewlix C seems to be in between Taito revisions. It got the old style F/C four part bezel/frame (mounted to the back of the monitor!) and a new style one part frame but without a groove for the glass.

I picked the one piece frame despite the other having the Japanese epilepsy warning sticker

Fitting a new monitor with the VUMM was really easy. The short product video gives a good guide on how to use it.

I got only one thing I would change:

the glass packers should have more height (for the loose glass frames).

When I put the monitor upright for testing, the monitor did not have enough pressure to keep the glass fully down and the glass slipped over a packer.

In summary:

I

Thanks very much for the feedback! I'm glad you like it!

Yes I've seen/had reports of a few Vewlix's that seem to be a hodgepodge of various models. I don't know if it was Taito using stock up between models or if it was Ops swapping monitors/parts around during their service. Some of the monitors I've seen that should need corner brackets don't actually need them and vice versa. I've even had reports of a someone with a Dia Blue P32L050 monitor that REALLY shouldn't need corner brackets but there cab does, go figure!

With that in mind I'm no longer telling people which monitors need corner brackets as there is conflicting information. I don't want to tell someone they need to buy corner brackets if they don't need them and vice versa. I've updated the monitor bracket information on the order form to give some guidance of how to check monitor bracket compatibility. The buyer can of course add the brackets to the order so they have them on hand for either scenario and a few people have done just that.

Thanks for the info on the glass packers. I originally made them 3.3mm thick and used 0.5mm thick adhesive which gives a total of 3.8mm and is just under the 4mm glass height. I don't really want them to protrude above the glass in case there is clearance issues with the replacement display fouling on them. I think what's happening is that the OEM foam between the frame and the glass is a couple of mm thick and so ideally I think the packers need to be a couple of mm taller too if the packers are fitted to the frame and not the foam. I just need to check that the thicker packers won't then foul on the underside of the corner brackets if someone installs one/some of them right in the corners. I might take a couple of mm off the bottom of the corner brackets to be on the safe side.

Still, minor things but if we can improve them then even better

Yes I've seen/had reports of a few Vewlix's that seem to be a hodgepodge of various models. I don't know if it was Taito using stock up between models or if it was Ops swapping monitors/parts around during their service. Some of the monitors I've seen that should need corner brackets don't actually need them and vice versa. I've even had reports of a someone with a Dia Blue P32L050 monitor that REALLY shouldn't need corner brackets but there cab does, go figure!

With that in mind I'm no longer telling people which monitors need corner brackets as there is conflicting information. I don't want to tell someone they need to buy corner brackets if they don't need them and vice versa. I've updated the monitor bracket information on the order form to give some guidance of how to check monitor bracket compatibility. The buyer can of course add the brackets to the order so they have them on hand for either scenario and a few people have done just that.

Thanks for the info on the glass packers. I originally made them 3.3mm thick and used 0.5mm thick adhesive which gives a total of 3.8mm and is just under the 4mm glass height. I don't really want them to protrude above the glass in case there is clearance issues with the replacement display fouling on them. I think what's happening is that the OEM foam between the frame and the glass is a couple of mm thick and so ideally I think the packers need to be a couple of mm taller too if the packers are fitted to the frame and not the foam. I just need to check that the thicker packers won't then foul on the underside of the corner brackets if someone installs one/some of them right in the corners. I might take a couple of mm off the bottom of the corner brackets to be on the safe side.

Still, minor things but if we can improve them then even better