Awesome, twins!

The 10mm x 1mm gasket turned up today so I got that fitted to the inside of the bezel:

I used [this] stuff if anyone wants to know.

10mm width seems to be the sweet spot. it's enough to fully cover the edges of the display but it doesn't encroach too much and interfere with the brackets. You can see now why I added the clearance to the bottom of the brackets, using anything over 10mm would have meant adding even more clearance:

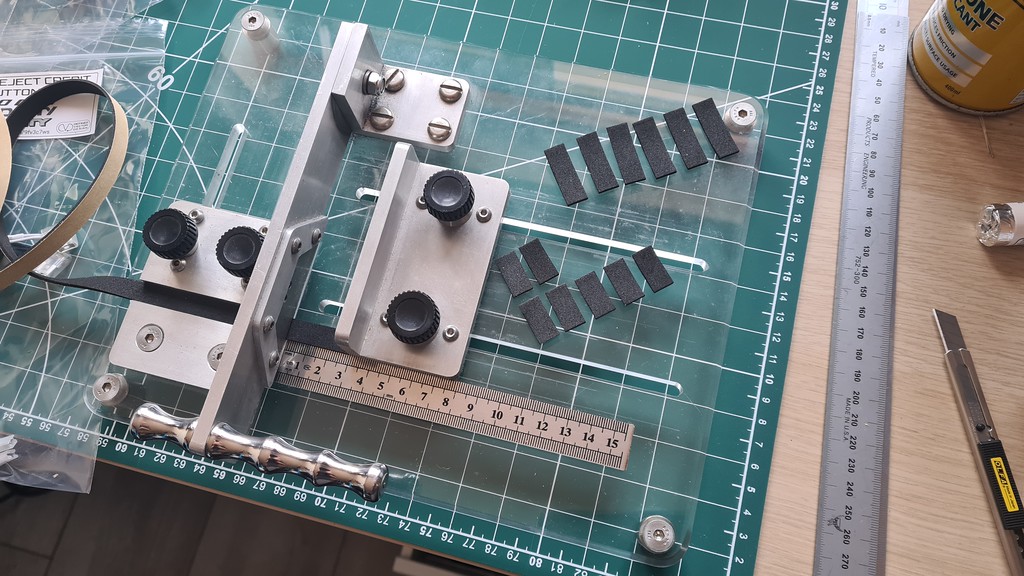

I intentionally left a gap between the underside of the clamp part of the bracket and the display. I was going to print some packers to take up the space but I found one piece of the foam on the bracket and one piece on the monitor was enough to hold it snugly. I also found that my heatshrink guillotine is ideal for accurately cutting foam tape too

Now brace yourself for the next photo...................

. . . . . . . . .

. . . . . . . .

. . . . . . .

. . . . .

. . . .

. . .

. .

.

I've added wood to a Vewlix!

Don't worry, this is is only temporary and is being used to work out how deep I need to make the VESA>Vewlix mount. I estimated it was about 60mm. I screwed a couple of bits of wood/WDF together and screwed them into pace from the back of the cab. I need to remeasure but I think these two bits came to about 51mm deep. I figured I can then measure the drop and then add it to the ~51mm. 'Dry fitting' the monitor also helps to see what type of profile I need to make the mount.

Luckily the power cable for the monitor is at a right angle and I also found a right angle HDMI adapter:

Looks to need about an extra 8mm so a ~60mm depth mount will be required which should leave plenty of room for cable routing:

Of course I had to fire her up too:

So it definitely looks like this has some legs. Thanks again for sharing your idea @Aurich I still want to work on a more universal solution later in the year but this will get both cabs playable again

I still want to work on a more universal solution later in the year but this will get both cabs playable again

I need to concentrate on some other stuff for a few days but I'll pick this up again next week. I'll get some more brackets printed for my other Vewlix and replacement display in the mean time.

I'm more than happy to share the STLs and/or .STPs if anyone wants to print or modify their own. I'll get them uploaded to Printables.com with a description etc when I get a bit more time but if anyone wants the files in the mean time just shout.

The 10mm x 1mm gasket turned up today so I got that fitted to the inside of the bezel:

I used [this] stuff if anyone wants to know.

10mm width seems to be the sweet spot. it's enough to fully cover the edges of the display but it doesn't encroach too much and interfere with the brackets. You can see now why I added the clearance to the bottom of the brackets, using anything over 10mm would have meant adding even more clearance:

I intentionally left a gap between the underside of the clamp part of the bracket and the display. I was going to print some packers to take up the space but I found one piece of the foam on the bracket and one piece on the monitor was enough to hold it snugly. I also found that my heatshrink guillotine is ideal for accurately cutting foam tape too

Now brace yourself for the next photo...................

. . . . . . . . .

. . . . . . . .

. . . . . . .

. . . . .

. . . .

. . .

. .

.

I've added wood to a Vewlix!

Don't worry, this is is only temporary and is being used to work out how deep I need to make the VESA>Vewlix mount. I estimated it was about 60mm. I screwed a couple of bits of wood/WDF together and screwed them into pace from the back of the cab. I need to remeasure but I think these two bits came to about 51mm deep. I figured I can then measure the drop and then add it to the ~51mm. 'Dry fitting' the monitor also helps to see what type of profile I need to make the mount.

Luckily the power cable for the monitor is at a right angle and I also found a right angle HDMI adapter:

Looks to need about an extra 8mm so a ~60mm depth mount will be required which should leave plenty of room for cable routing:

Of course I had to fire her up too:

So it definitely looks like this has some legs. Thanks again for sharing your idea @Aurich

I still want to work on a more universal solution later in the year but this will get both cabs playable again

I still want to work on a more universal solution later in the year but this will get both cabs playable again

I need to concentrate on some other stuff for a few days but I'll pick this up again next week. I'll get some more brackets printed for my other Vewlix and replacement display in the mean time.

I'm more than happy to share the STLs and/or .STPs if anyone wants to print or modify their own. I'll get them uploaded to Printables.com with a description etc when I get a bit more time but if anyone wants the files in the mean time just shout.

I have questions!

I have questions!