xodaraP

Legendary

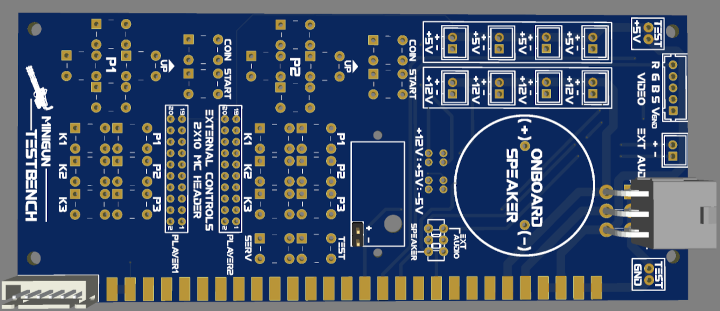

I like this a lot. What connection are you using for video?I've been fiddling with Easy EDA a lot lately too, pivoting off of Frank's work. Getting better with it (I think). Working on this right now:

Just want my test bench to be uncluttered. The one I've used for so long has just been a stripped out harness from a cab. I put a 3P3T switch for all 3 voltages. A hole for calibrating the meter. A DPDT switch for onboard audio to output to an external speaker or to attenuate the signal for the onboard speaker. Test points for a probe. Extra +5v and +12v connections. Ability to use external controls. Most importantly, momentary switches for signal inputs.

.

. Sadly I finished my new design a couple of minutes ago. To bad , maybe I'll change it in the future

Sadly I finished my new design a couple of minutes ago. To bad , maybe I'll change it in the future