I was thinking of something along the lines of something like this, these are very basic designs, did them in like 5 minutes just to get some ideas going.

Cut out on the side would be for Jamma connection,etc..

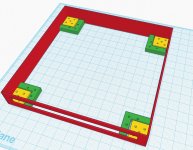

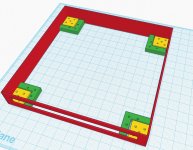

This is a fixed design with maybe break-away tabs if needed, with holes for pcb mounting feets to install to.

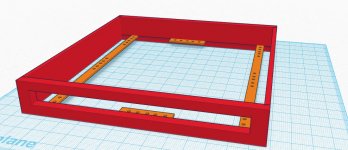

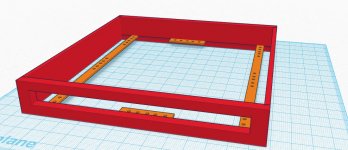

This design would have adjustable mounting rails?!

Cut out on the side would be for Jamma connection,etc..

This is a fixed design with maybe break-away tabs if needed, with holes for pcb mounting feets to install to.

This design would have adjustable mounting rails?!