AlxUnderBase

Enlightened

Awesome theard

This is 100% the way to go. Why do all the work to recap and then get lazy about doing it right? Kits are often wrong. Boards have variations. People pick cheap caps. Clearly you are way beyond being lazy about this, top notch effort. You are, actually, making me feel very lazy right now about my Astros lol.

It looks like you have a lot of knowledge about paint, painting and body repair. This is a major area of improvement for the restoration community IMO, would love to know more about this sort of thing in a future series.

Cleaning

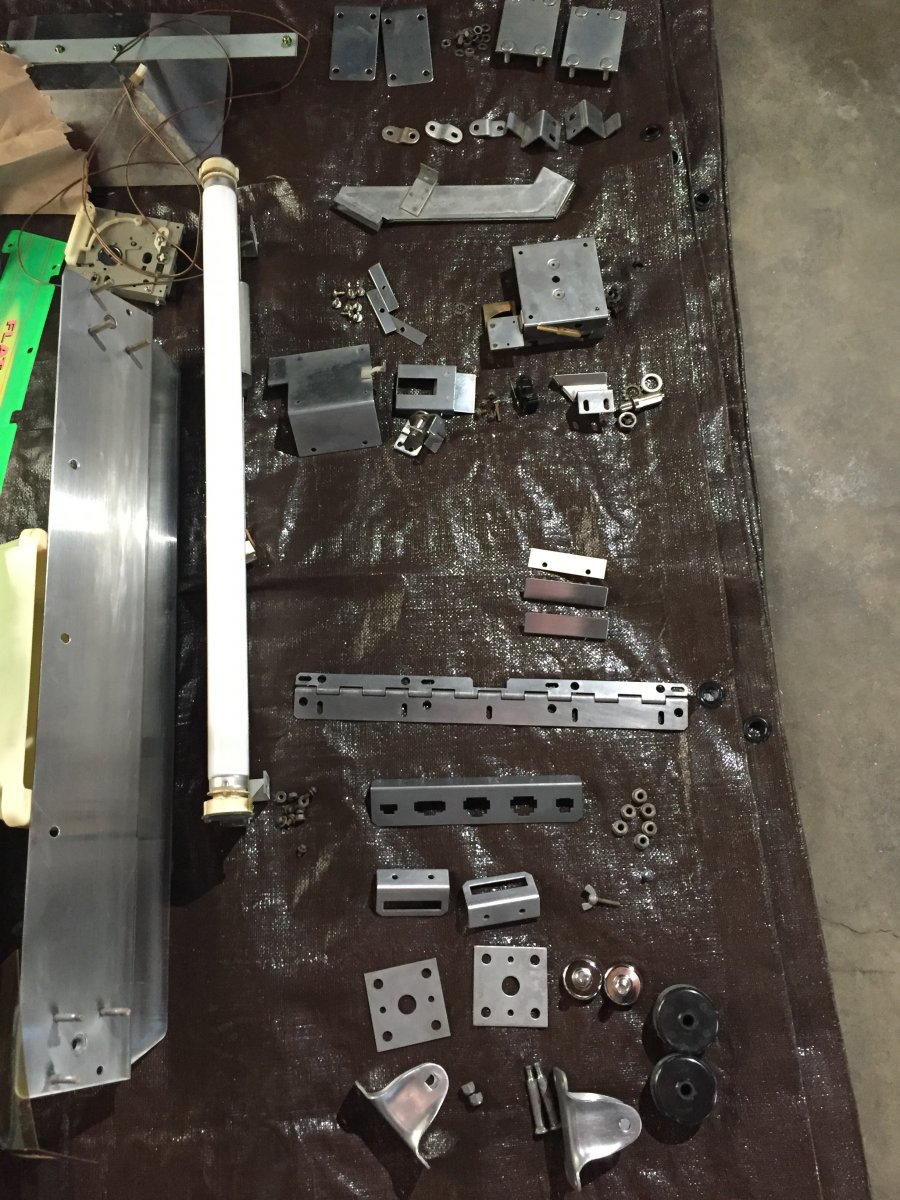

Not much to add about cleaning a cabinet that hasn't been covered before. Nearly every piece of metal was covered with rust. Soaking in vinegar for a few days, followed by some scrubbing with Bar Keeper's Friend, then rubbing with metal polish was my way of treating it. The vinegar took off all the paint on the speaker grills.

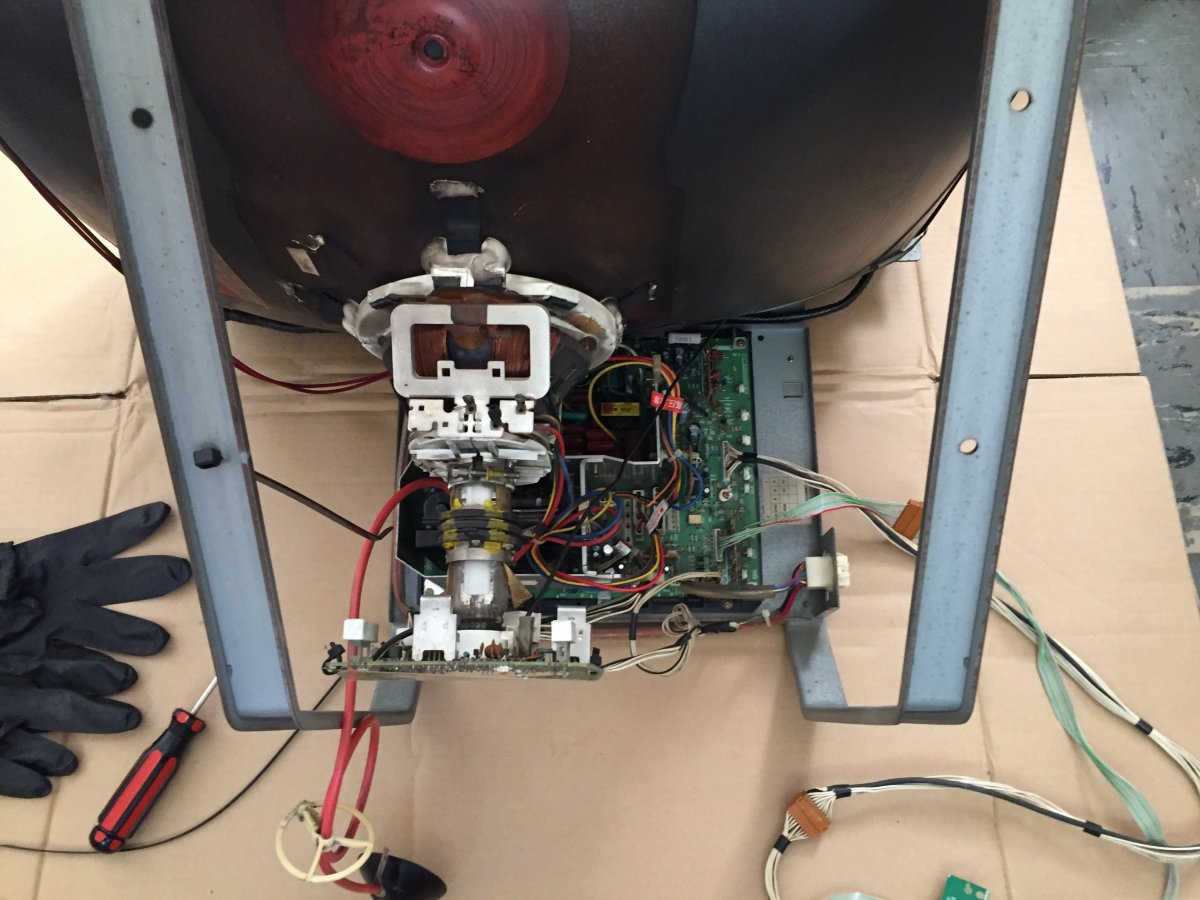

All clean.

I know a lot of people like to clean their monitors with de-greaser and a garden hose and put PCBs through a dishwashing machine and I'm sure that's all perfectly fine. But I'm not into it. A brush, dry rag, and electric duster takes out most of the loose dirt. A damp rag around the tube, frame, wiring, and other bits for the stuck-on dirt. For the PCB, 99% isopropyl alcohol. This cleaning method certainly takes longer than the garden hose/dishwasher approach and doesn't remove 100% of the dirt. But that's ok with me.

This photo is after replacing the capacitors. With the PCB taken apart I was able to clean the board well with alcohol.

The metal piece that attaches to the bottom front (leg adjustment bracket?) needed some extra attention. I spent a long time trying to sand away the scratches with an orbital sander and 80 grit. Then finished by wet sanding by hand to bring back the brushed stainless look. Ideally I should have used a grinder to level out the surface before sanding but I don't have a grinder. I was disappointed with my results but fortunately once indoors and in normal room lighting it looks fine.

It's weird to me how people mess this stuff up so badly. I mean, it's really not that hard to do it right. It's a simple design, there aren't that many details to pay attention to.My 100 yen sticker is looking tired and I planned to replace it. However, after the experience with the lower billboard I decided to compare my original sticker to the two reproduction stickers that look like good quality.

I agree. It is weird. I sent a friendly note to arcadeartshop about the design. Maybe it will get updated one day. The stickers look nice otherwise.It's weird to me how people mess this stuff up so badly. I mean, it's really not that hard to do it right. It's a simple design, there aren't that many details to pay attention to.

These are some stickers I made for my arcade's brand, just for fun. Even with the text change I bet they're more accurate to the original than either repro you showed lol.

Thanks for the TIP. Actually I was worried that I messed up after the Vinegar phase.No Brasso. I soaked everything in vinegar for a few days. Some pieces got a second soak. I had a lot of rust. Then used a brush with Bar Keeper's Friend mixed with water. Then used a Chemical Guy's metal polish to rub away the remaining rust with a microfiber towel. You might not need any polish or Bar Keeper's Friend. After the vinegar soak, try to rub away the rust residue with a dry cloth.